Liquid Silicone Rubber (LSR) molding is a unique process to produce durable and high-temperature resistant plastic applications. They take advantage of a material known as Liquid Silicone Rubber (LSR). The mold being used shape process of LSR. The idea is that as the LSR hardens, it cures as a complete, single part. LSR moulding turns out to be very efficient and reliable for the production of high-quality items.

These is one way how LSR molding transformed the manufacturing processes. This method enables the manufacturers to produce the quality products, which can be complex in terms of shape and design. It can do things that older, conventional methods may struggle to do. Through LSR molding, producers can create products that are not only durable but also sturdy. These materials can withstand chemical exposure and other extreme environments, making them very versatile in a wide range of applications.

Low-Temperature Injection Molding is one of the most significant and applicable methods of molding in the sector of medical devices. There are several reasons as to why this approach is more favorable. However, it offers one significant advantage, as it produces safe and clean components. This matter is of utmost importance in healthcare as anything that enters a person’s body should essentially be free of germs and dirt. Parts processed with LSR molding have smooth surfaces that prevent contamination and enable safe usage.

Additionally, LSR molding has the unique ability to easily produce a high quantity of products in a short timeframe, which is another tremendous advantage when it comes to manufacturing medical devices. That means hospitals and clinics can obtain supplies when they need them, without protracted waiting times. The process ensures that the quality is consistent for every part manufactured, ensuring that doctors and patients can rely on the proper functioning of the devices. LSR molding also produces components that are capable of enduring high temperatures as well as radiation, an integral part of many medical applications.

Companies also use specialized computer programs that simulate and optimize the LSR injection molding process to save money. These initiatives help manufacturers determine how to use less material, which translates to cost savings and less waste. Companies also want to produce more sustainably, i.e., be better to the environment, and still produce quality product.

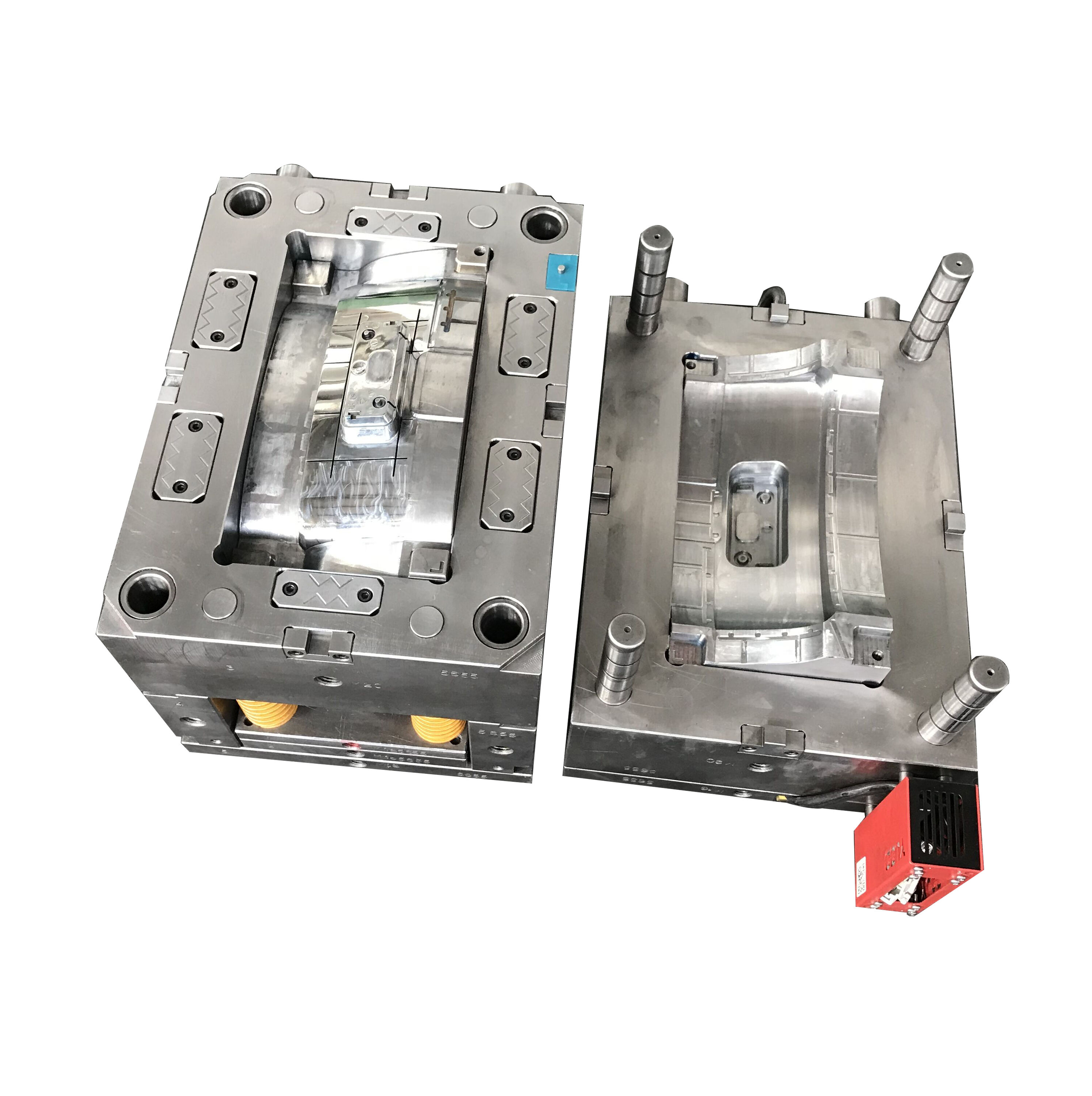

The best practices to follow for LSR molding are highlighted below. First, they have to select an appropriate LSR material for what they need and for their application. The material that you choose plays a huge part in the finished product. Second, they must design the mold correctly. These are the design aspects of the part that allow for successful molding, including the design of the gating system, which is the portion through which the liquid LSR enters the mold, and the size of the injection pressure.

Molding the quality of a final product, the injection pressure is too much crucial. If it is too low, the part will have defects like sink marks or voids, impacting aesthetics and function of the part. On the other hand, if the pressure is excessive, it can cause complications such as material overflow or worse, damaging the mold.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.