Injection molding is a common method for producing plastic objects, ranging from fun stuff like toy cars all the way to practical items like spoons. But did you know injection molding is used to make important medical tools too? These tools are things like syringes which assist in giving medicine or heart pumps which help maintain the heart working effectively. Every day this special process is changing the way doctors and nurses treat people. Join us as we dig into how Moldie is disrupting the future of medical device injection molding.

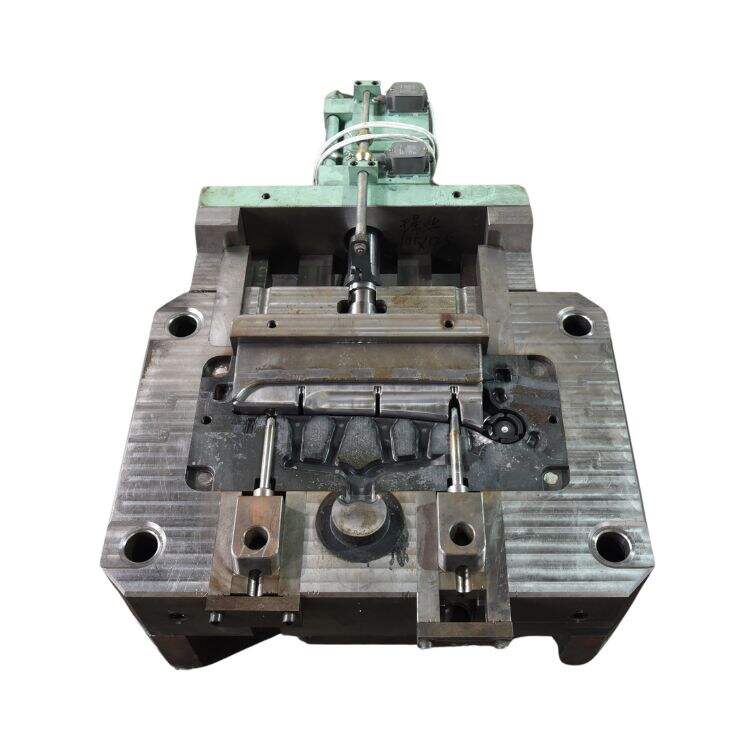

It used to take an awfully long time and a great deal of money to make medical devices. It was a 10-step process that was complicated. However since the discovery of injection molding, the process is much simpler and quicker. So, how does it work? The industrial process begins with small plastic balls, which resemble tiny pellets, being melted down into thick liquid. Then, you take this melted plastic, and you carefully press it into a mold. A mold is a container that goes inside of the liquid plastic, forming it into the perfect shape, like the shape of the device that we want to build. Moldie employs the most sophisticated technology to guarantee that the plastic is melted and molded precisely each time so that it's effective and dependable.

Injection molding compared to older methods of manufacturing has a lot of advantages. One of the major advantages is speed. Since injection molding is a much quicker method of production, it allows physicians and physicians assistants to reap the benefits of the medical items they require without the extended lead time. And that is especially important in emergencies, when every second counts. Another benefit is accuracy. It ensures the required size and shape of the medical devices. This specificity is critically important since medical devices need to fit precisely to function adequately. Furthermore, injection molding becomes highly effective at that point. That means, in the process of making these medical devices, there is very little plastic, or waste, left over, which is better for the environment.

Injection moldings are ideal for medical devices, and there is no single reason why they are a consistently frequently preferred choice. Perhaps the most important reason is safety. Injection molded plastic is of overall excellent quality, making it sturdy and dependable. It is also tested extensively in order to ensure that it is safe for medical application. This testing is to ensure that made devices are safe for patients. Another benefit of injection molding is the precision. This level of precision enables the construction of medical devices to exact specifications, an important aspect of saving lives. Doctors and nurses can trust the medical devices they work with, being assured they are manufactured correctly.

There are a variety of medical devices that are critical in healthcare that are manufactured by injection molding. The most common types of devices made are things like syringes, which are used to give people a shot or take their blood, heart pumps that help people with heart problems, and surgical instruments that a doctor needs while they are operating. These devices are critical for doctors and nurses in patient care. Injection molding is also applied in the production of research medical devices. This research is so important because it is through this that scientists learn how to effectively cure diseases and find next generation treatments that can potentially save millions.

The Impact of Using Injection Molding to Manufacture Medical Devices in the Healthcare Sector If these devices can be made quickly and accurately, doctors and nurses may be able to provide better care and save more lives. Moreover, it is cheaper to manufacture by injection molding. That means factory-produced medical devices, far less expensive than custom-made devices, can be sold for less. Making medical devices more affordable gives more people access to the tools that they need to stay healthy.” Injection molding is also helping to contribute to medical advances by providing scientists with precise and safe tools they can utilize in their research.

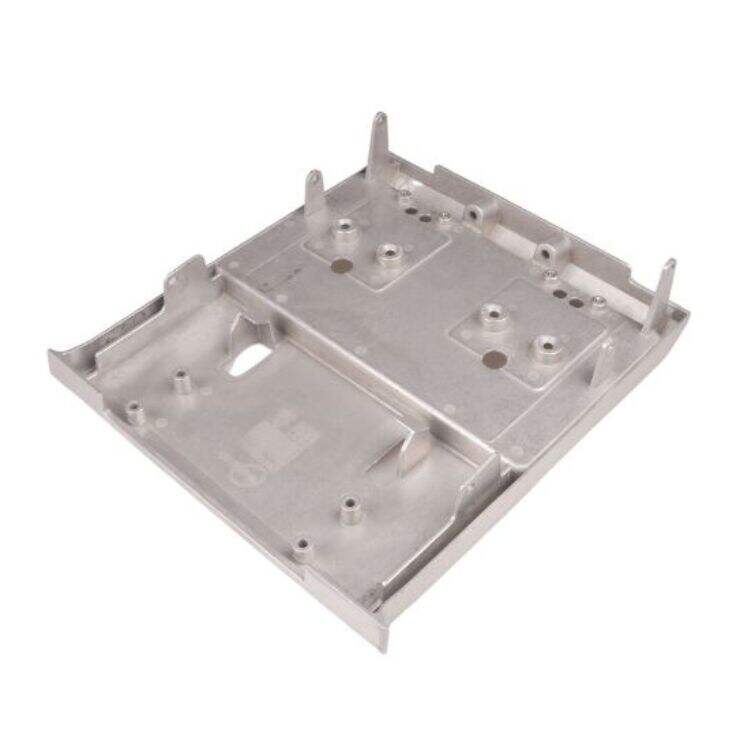

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.