Plastic is an invaluable material in our daily lives. Plastic is an abundant substance and it is found in the production of various objects including, but not limited to, toys, cups, water bottles, containers, and parts of a car. It contributes to easier, and more fun, lives. But creating plastic parts can be difficult and costly. That’s where a company called Moldie comes in. They've discovered a clever, inexpensive method of manufacturing complex plastic pieces. And this technique is called PP injection molding

PP injection molding is a unique process that produces a wide variety of plastic components. It is quite flexible, which allows simple shapes and more complicated forms. This begins with a common plastic material known as polypropylene, or PP for short. First, the PP used is heated and it becomes soft and molten, similar to ice cream melting in the sun. Next, the molten PP is fed into a mold. A mold is like a giant cookie cutter: it has the shape of the plastic part we want to make. The PP hardens when the mold is cooled down after it has been filled with the melted PP. Then it hardens from a soft liquid back into a solid to create the finished plastic part.

The best part about manufacturing plastic parts through PP injection molding is that it creates identical pieces. We refer to this as high precision. The same process would be repeated for every part (important for having the pieces fit together afterwards). This is extremely helpful when the components need to collaborate, such as when they are assembled into a toy or a piece of machinery.

The PP is also known for their use in injection molding. The most obvious benefit is that PP is a very robust material. PP is also a plastic that, when used in manufacturing, will create long-living parts, meaning even parts we use daily will physically last for a long time. Toy made from PP can play many times without broken down like dropped. Also, PP is low in weight therefore it is used to manufacture of items like toys, cups etc. It’s more pleasant to hold and carry, and especially a godsend for kids.

Additionally, PP also needs to be found, PP requires to be understood so that successful making of these plastic parts is done. PP is a thermoplastic polymer. Meaning it can be melted down and shaped over and over again without losing its unique properties. You can repeatedly do this if you heat it up and then allow it to cool. Unlike certain other materials which can be compromised by heating, this is not the case here. PP is also resistant to many chemicals so that's another plus. That means it can be used in lots of different locations such as kitchens or laboratories where it may encounter many different substances. Diversity — PP is very robust and resilient; therefore, components made with PP injection molding can be employed in numerous applications.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

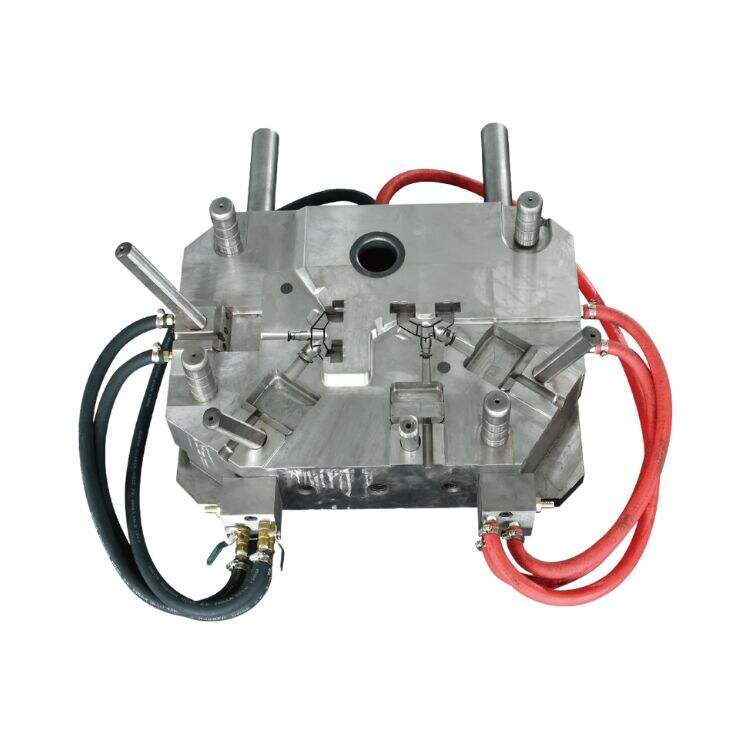

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.