Automotive Plastic Injection Molding is a unique, specialized method for making essential car parts. This is a very useful approach as it ensures that the components of the car align perfectly together. If car parts fit well, they work better, and especially save a lot of money for the car companies. Let’s learn more about this really nifty process!

Automotive Plastic Injection Molding has several advantages that make it ideal for producing automotive components. One big advantage is that it manufactures car parts very precisely. That means all the bits will fit together well, and that's important to the way a car operates. The puzzle pieces should not fit well right. The other good aspect of this approach is that it can create auto components speedily. This is because the process works excellently and uses great materials which are durable.

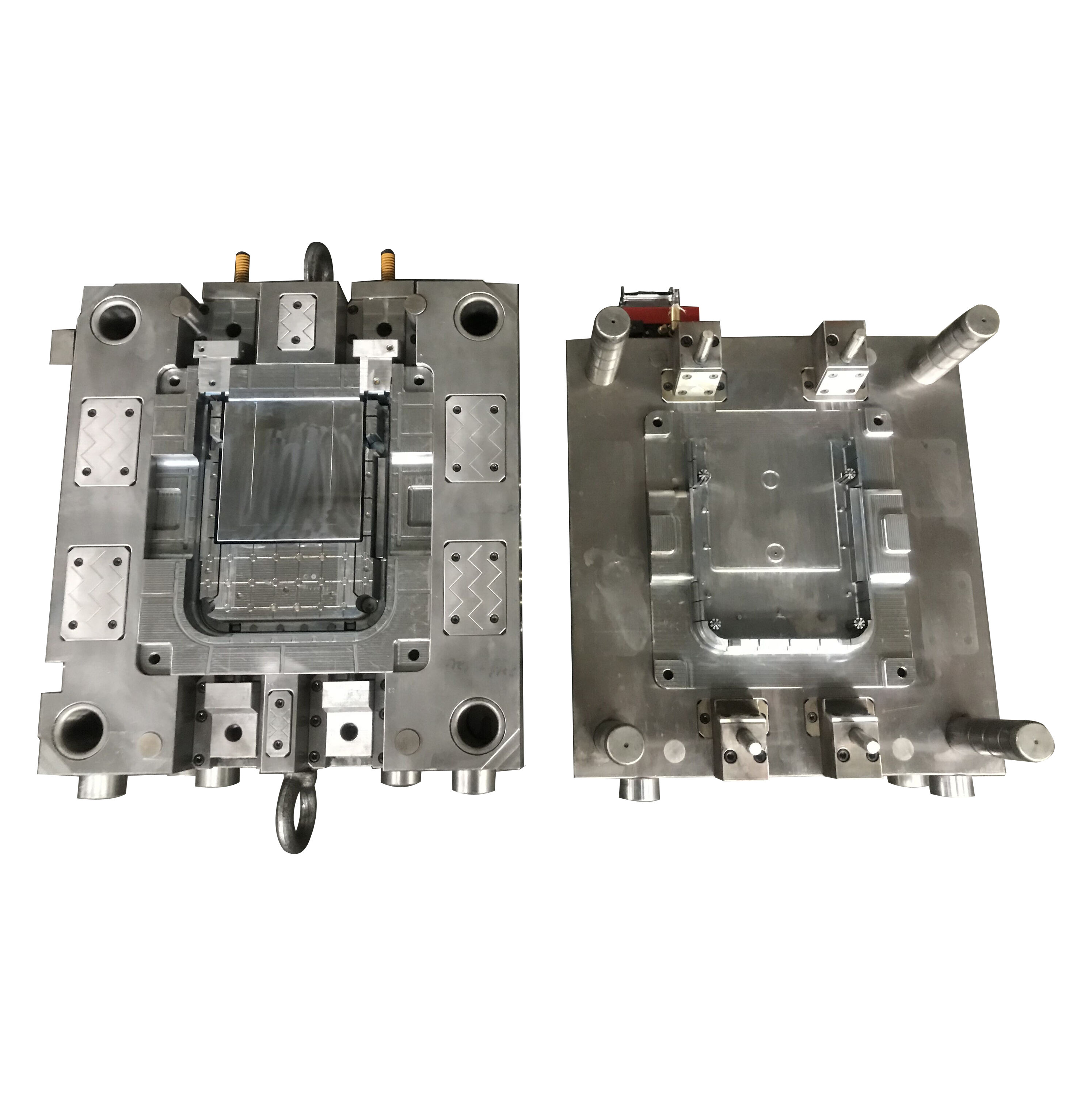

For car parts made with this method, they use a specific machine. This machine has a task to perform: it melts plastic and then deposits the liquefied plastic into a mold. A mold is essentially a shape that the plastic cools into. As the plastic cools down it becomes a car piece! The molds are shaped perfectly to the exact compliment intended for the car part required, making this process extremely precise. This ensures that all the car part combinations fit well with each other and many are engineered for safety and performance reasons.

And Automotive Plastic Injection Molding is very fast again. This allows it to produce a lot of parts in a short time, and with minimal waste. Waste are items that are not properly referred to and thrown away. This system cuts down on waste, which is good for the environment and for the companies producing the components. It also saves money. That is because it requires less material and can produce multiple components in one go. Unfortunately, in order to sell cars people actually want to buy at prices they can afford, car companies need to save money, and lots of it.

The way it works is you take plastic, melt the parts and then put it into a mold. Not all plastics are created equal! Plastics vary in strength and also suitibility for creating particular parts of cars. Common examples of plastics used in this process are Polypropylene, ABS, Nylon. These kinds of plastics are very strong, and capable of withstanding a lot of pressure, something that's crucial, since car parts need to be robust enough to keep drivers safe if an impact occurs. Quality materials (materials that are strong) ensure that the parts of a car will last longer and perform as required.

At Moldie we molded car parts with Automotive Plastic Injection Molding. We pay attention to great materials, and our machines are very accurate. That means all of our car parts are compatible with one another and perform as they should; the first time. We also ensure ours is a quick and cost effective process, which puts us in the favourable position to power car guys making cars affordable for the everyone. Take pride in what we do and ensure every component you create is quality.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.