THE factory, a plastic moulding dies, is some special kind of place. The Moldie plastic moulding factory is a large building full of machines and workers. That special machinery is used to melt up plastic, then mold it into anything and everything in this factory. This enables the factory to produce a wide range of items, including toys, containers, and so on.

Moldie abc plastic moulding is a busy place with lots of people all working in harmony. Everybody has an essential role to play. You will see big machines that take plastic and melt it down to liquid. Once the plastic is melted, it is formed into moulds, a special shape that the plastic will take after cooling down. When cooling down, the melted plastic hardens into the perfect shape of the mould. After this, workers delicately remove the plastic parts from the moulds and finish them by cutting edges or painting them to make them look good. If you go, you'll probably be wearing fancy clothes and a safety hat with bright colors so no one bumps into you while you walk around, gazing at the powerful machines as they work.

Innovation is a broad term that generally refers to creating new ideas or better ways of doing things we do already. Innovation is the lifeblood of Polish manufacturing, and it will be at the Moldie plastic moulding factory where we will make sure that this is the case. The workers are constantly searching for system improvements or new ways to make their job easier and more efficient. They usually work on computers with specialized software to make new products before they are built. Once they have a design, they utilize their machines to produce real items from those designs. When they invent something, they do not just let it go. They always try out the new things to check if they aren't weak, dangerous, and can be used by people. By implementing this practice, they ensure that every content they create is up to the mark.

Every day at the Moldie plastic moulding factory is a day of teamwork and cooperation. Plastic products are the result of a lot of people doing a lot of different jobs. Some employees design the products while others run the machines that churn out the plastic. There are also employees who sand down the plastic parts or paint them to make them look good. Each person has a unique role that is vital for the success of the factory. Everyone wears special clothes and safety hats to avoid getting injured while working with the machines. Also, they take regular breaks to refresh and recharge and frequently lunch together in a break room where they can relax and catch up on their day.

Eco-friendly is an action or thing that is good for the environment. The workers at the Moldie plastic moulding factory care very much for the environment. They are constantly seeking how to make the most sustainable choice. For example, when they make products, they try to use as little plastic as possible to create less waste. They also try to use recycled plastic whenever possible, which reduces the amount of new plastic that has to be created. Plus, they have special machinery that uses less energy, which is better for the environment. The factory also recycles water used in the machines for reuse. They even have a special program to recycle old plastic parts as they become unnecessary which helps keep the factory and the Earth cleaner.

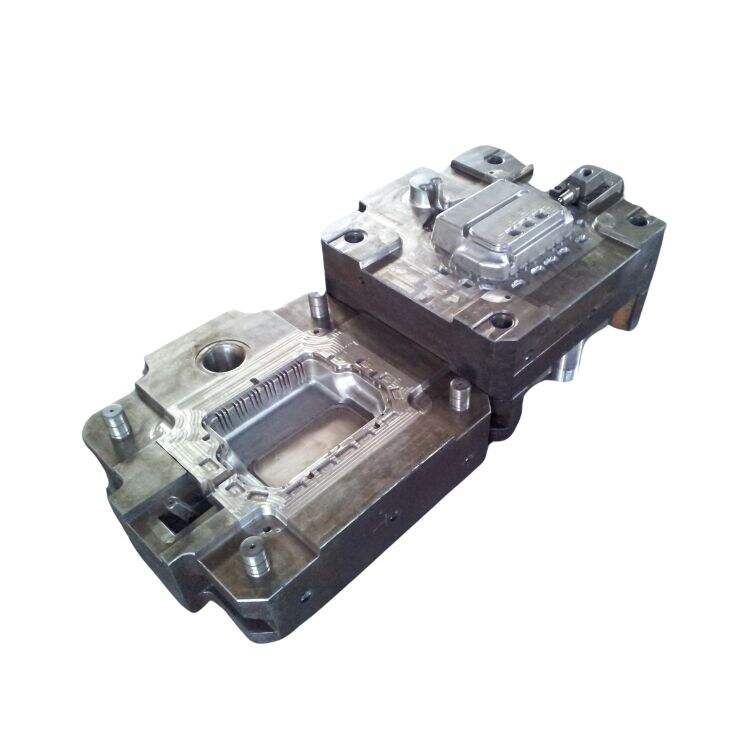

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.