What is aluminum investment casting? It was a special way of fabricating with aluminum. First, king of all metals, the aluminum, is melted up to the boiling point, creating liquid metal. Then, liquid aluminum is carefully poured into a shaped mold to create whatever we want. This is a very important process as all aforementioned shapes can be created with our designs. We specialize in aluminum investment casting at Moldie. So, let’s find out more of the perks of this process, how it aids us in producing small batches of products, how it can form highly detailed shapes, and how it is utilized across numerous disciplines throughout the globe.

High quality products having very smooth surfaces are one of the most important benefits of aluminum casting alloys. This matters greatly, in that when you melt aluminum and pour it into a mold, it fills the mold extremely accurately. But what this also means, is that the final product has a defined shape and it’s also very impressive. This accuracy makes the products manufactured using aluminum investment casting very precise, and they fit together very well, which is essential on many applications. Also, the surface finish of the products is quite better than the items made with other casting way, they are functional and catchy as well.

There are lots of advantages for Moldie aluminum investment casting process, which makes it an excellent option for manufacturing. First and foremost, it is low cost because it saves you money. The molds created by this method are wax-based. Since wax is a somewhat cheap material, this also brings down the total price. The reason it is cost-efficient is that the molds are reusable many times. This means that once you have mold, you can use it to produce more products, which saves even more money. In addition, aluminum investment casting is an extremely efficient method. This aluminum die means multiple molds can be created at once, increasing production and making more products at a fraction of the time.

Sometimes businesses need to produce products in small batches. With other methods, this can be difficult and expensive. Putting together aluminum investment casting for small batches can be cheap and efficient. It can deliver high-quality products even when a limited number are required. This repairing cast aluminum is extremely beneficial for small businesses and startups whose needs do not often require large volumes of products. Production starts rapidly since the molds can be produced quickly. This is also a way to reduce costs, so these smaller companies can produce quality products for relatively small amounts of money.

However, one of the other great benefits of Moldie aluminum investment casting is the very fine complex shapes and details that can also be achieved. This is done either in wax, which makes it easy to create detailed and elaborate designs that are difficult to achieve using other casting techniques. Aluminum investment casting is capable of producing highly detailed and accurate shapes, which is beneficial for applications that require special design. If an organization wishes to create a part with angles and curves, die cast aluminum alloys is up to the task. Its capability of forming complex shapes makes it suitable for a variety of products.

Aluminum investment casting is a process that can have multiple applications across different industries. They are widely used to make components for airplanes, auto parts, production of medical devices, and electronics. All of these items need strong and vigorous parts and aluminum pressure die casting delivers it. It is also used in the jewelry industry to create finely crafted pieces that need so much detail. Aluminum investment casting is becoming increasingly prevalent in many different industries as companies identify its advantages, because it is so useful in so many different places.

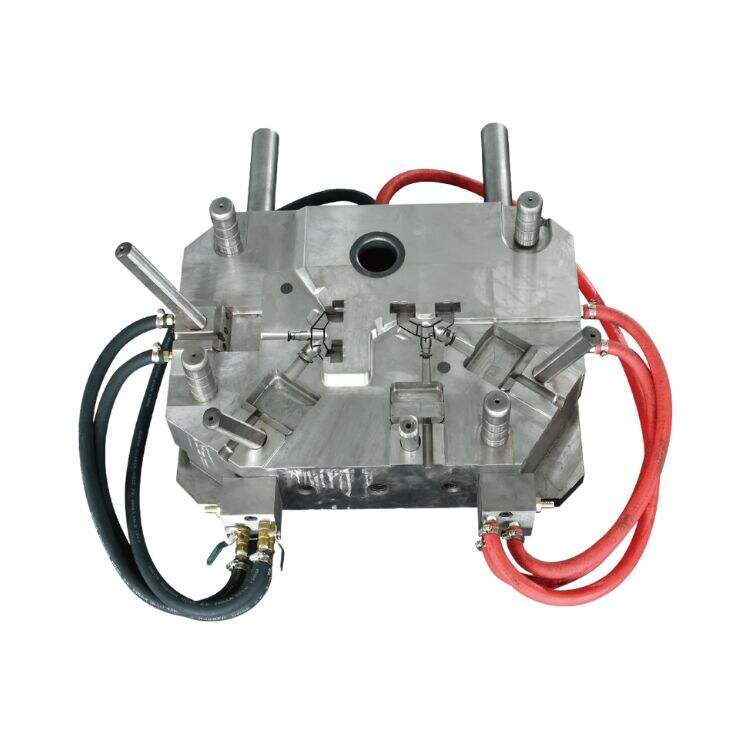

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.