Have you ever wondered how plastic toys, cups, and containers are made? You may be surprised to know there is a company named Multi Mold Plastics Inc. — nicknamed Moldie. They are a company that produces specialized plastic products with the help of intelligent methods and techniques to produce multiple products.

At moldie they think every plastic product should be special and unique just like every person! This is why they listen closely to their customers, who then work hand in hand with them on designing and making beautiful plastic products that are just right for what the customer needs. Using advanced computer programs as well as state of the art machines, they ensure 3D versions of each product come to life. This is to ensure that they have everything in place before they start creating the actual products.

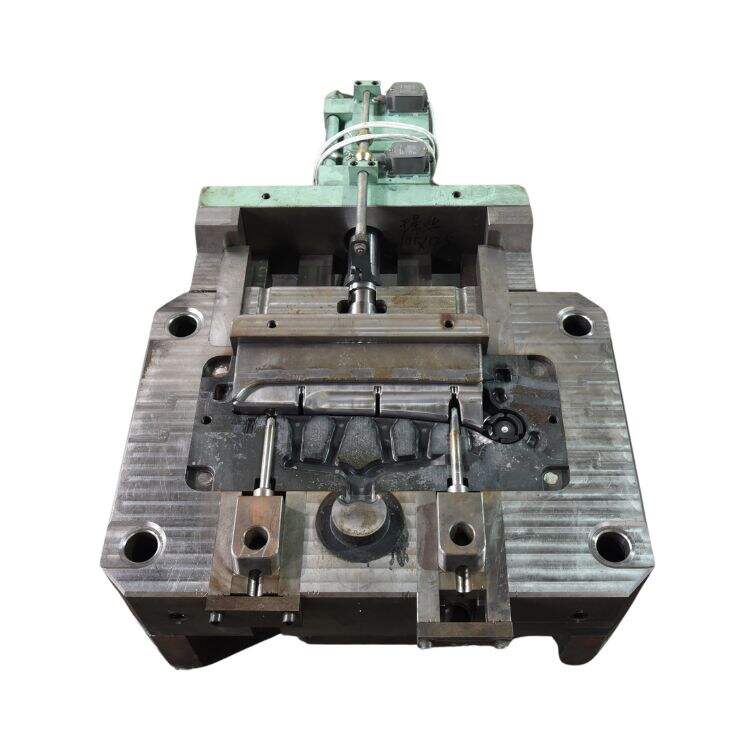

First, they do this through a process called injection molding. The process involves taking small and plastic pellets and melting them down before molding them into the exact shape of the product. Similar to how a cookie cutter makes cookies of different shapes, Moldie makes plastic items with a mold. It is precision-based, meaning that this method is ensuring the quality of the product is the same every single time it is produced.

It’s a method of a hybrid injection molding with a conventional injection molding mated to a novel compression step. As a result, they can make things terms even quicker than previously. This method goes one step further by minimizing waste, which helps our planet too! Moldie is doing its part in saving the planet, by using less material and producing less waste.

Moldie knows that every one of their customers has their own needs and vision for what they want to create. That’s also why they partner with their clients to develop solutions that address those particular needs. They think that teamwork is a vital part of producing the best products.

From day one, when a customer brings them an idea for the first time, Moldie keeps in touch with them. They assist the customer from the design stage, where they design the specification for the product, all the way to the point of delivery of that product. The two companies work so closely together that they meet the highest quality standards at each step of the way of the product. That's why Moldie wants to ensure that customers are satisfied with what they get.

In recent years, they have developed a new kind of plastic made from renewable resources. This is because the materials they use are able to be replaced and are more eco-friendly. Even more importantly, this new plastic is biodegradable, which means it will be broken down naturally over a period of time rather than sitting in a landfill for decades. This is a massive stride in the right direction, towards minimizing plastic pollution and building a sustainable environment for all.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.