Moldie is a company that focuses on the technique of injection molding. This method can be used to create so many different things, but is especially helpful in creating car parts. Injection molding is when melted material is injected into a mold to take different shapes. As the molten material cools, it takes the shape of the mold, solidifying into a cast product. This process plays a significant role in the automotive industry, where it helps manufacture numerous components in a swift and effective manner.

So, here are several reasons why injection molding is excellent for manufacturing car parts. One of the most common reasons is the speed in which it can produce parts. As the melted material fills the mold, it quickly solidifies in order to take the proper shape. This allows car makes to 3D print a high volume of parts in a matter of hours, especially useful when they need many components for their cars.

Injection molding is also extremely accurate in the way it operates. The molds are made to shape and size molds대여. It is important to note that the process also allows for the deposition of materials that are both highly accurate and consistent. This precision matters immensely for car parts, as even minor differences in dimensions or figures can result in impactful complications when a car is in action. If, for example, a part doesn't fit properly, the car may particularly work poorly and breakdown.

There are many benefits of using injection molded car parts, which is why they are a popular choice for car manufacturers. First of all, these components are extremely tough and long-lasting. This is essential due to the fact that car components require to be capable to sustain a ton of wear and tear over the years. They use injection molded parts, which are resistant to stress and pressure, making them ideal for the high-stress environment of an automobile that has different changes in conditions as it moves on the road.

Injection molding has another advantage of producing thin walled parts. Thin features are required in many automotive applications to reduce the vehicle weight and hence the efficiency of the car. Thin and strong parts were difficult to create with traditional manufacturing methods, however it is possible with injection molding. It aids automobile manufacturers in producing superior cars that will be able to bring traction and control on the road.

How injection molding technology can speed up and optimize automotive parts manufacturing. Thanks to how quickly and accurately car manufacturers are able to produce parts, this helps car manufacturers get their cars` to the market far faster than they were able to before. That speed is needed in a competitive automotive industry, where being the first to sell a new model can have a major impact.

Due to this very reason as well, another very good thing about injection molding technology is that these parts are very strong and durable. These properties are essential for automotive parts which needs to endure daily usage and the rigors of driving. Additionally, these materials allow car makers to manufacture parts that are durable and functional even in extreme environments, meaning drivers get a safe, comfortable ride.

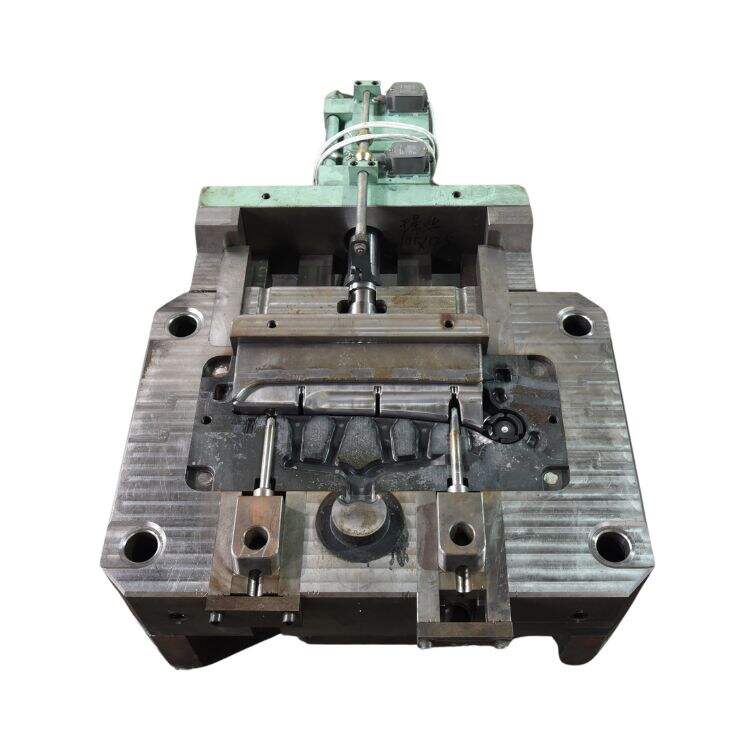

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.