In this blog, we are going to discuss an innovative technology known as ! This advanced equipment is used to create extremely small components used in a wide variety of products. These items include toys, electronic devices, as well as even essential medical equipment! One example of a recent company utilizing this incredible tech is Moldie. They are famous for building brilliant products that millions of people love and use on a daily basis!

Micro injection molding uses micro molds to produce micro parts. Like a factory, it is the shape or form to shape the material into the part we want mold. These molds are produced from certain materials that can withstand extreme heat and pressure. This is significant because it enables us to manufacture components that possess small features and intricate geometries that are extremely challenging to produce via alternate means.

Micro injection molding is great because it can create a large number of parts quickly and accurately. That speed and precision are critical for companies that have to create a lot of products in a small amount of time. Micro injection molding allows companies to produce small parts for their toys, like toy parts, so companies don't have to build them thousands of times. Moldie makes its parts through a process known as micro injection molding, which means they are not only strong but long-lasting and built to withstand frequent use.

Micro-molded parts are also generally more precise than parts made by alternative means. The parts fit together better together and work more smoothly in the products. For example, parts that go into a toy will match properly with other parts so that the toy performs as planned. In addition, these parts offer greater durability than standardized components, as they use superior materials that resist wear and damage. Moldie takes advantage of these incredible micro-molded parts to provide folks with strong and affordable (win-win!) products.

Micro injection molding is capable of producing parts in various shapes and sizes, which is one of its greatest advantages. Be it small or large, this technology can squash it! And their versatility, and it has made them the right choice for a lot of manufacturing companies that need to manufacture a lot of predictant. Moldie leverages this technology to create and design innovative products customized to a customer's specific requests, giving them precisely what they desire.

Furthermore, micro injection molding has environmental benefits because it uses less material and less energy to produce each part. This is particularly relevant today, as we must discover methods for products to be sustainable and friendly to our planet. As part of this movement, Moldie is leading the charge with micro injection molded products that are clean and ethical. This provides environmental safeguards while continuing to provide people with great products to use.

Other methods of manufacturing always require a lot of time and money, but with this technology, we will be able to make products faster and cheaper than ever before. So what can we expect in the future — new technology will continue to help us, we can make products quicker, better and more sustainably. In this new age, Moldie is at the forefront, with micro injection molding enabling the manufacturing of products that reach the edge of what is technically feasible in our field.

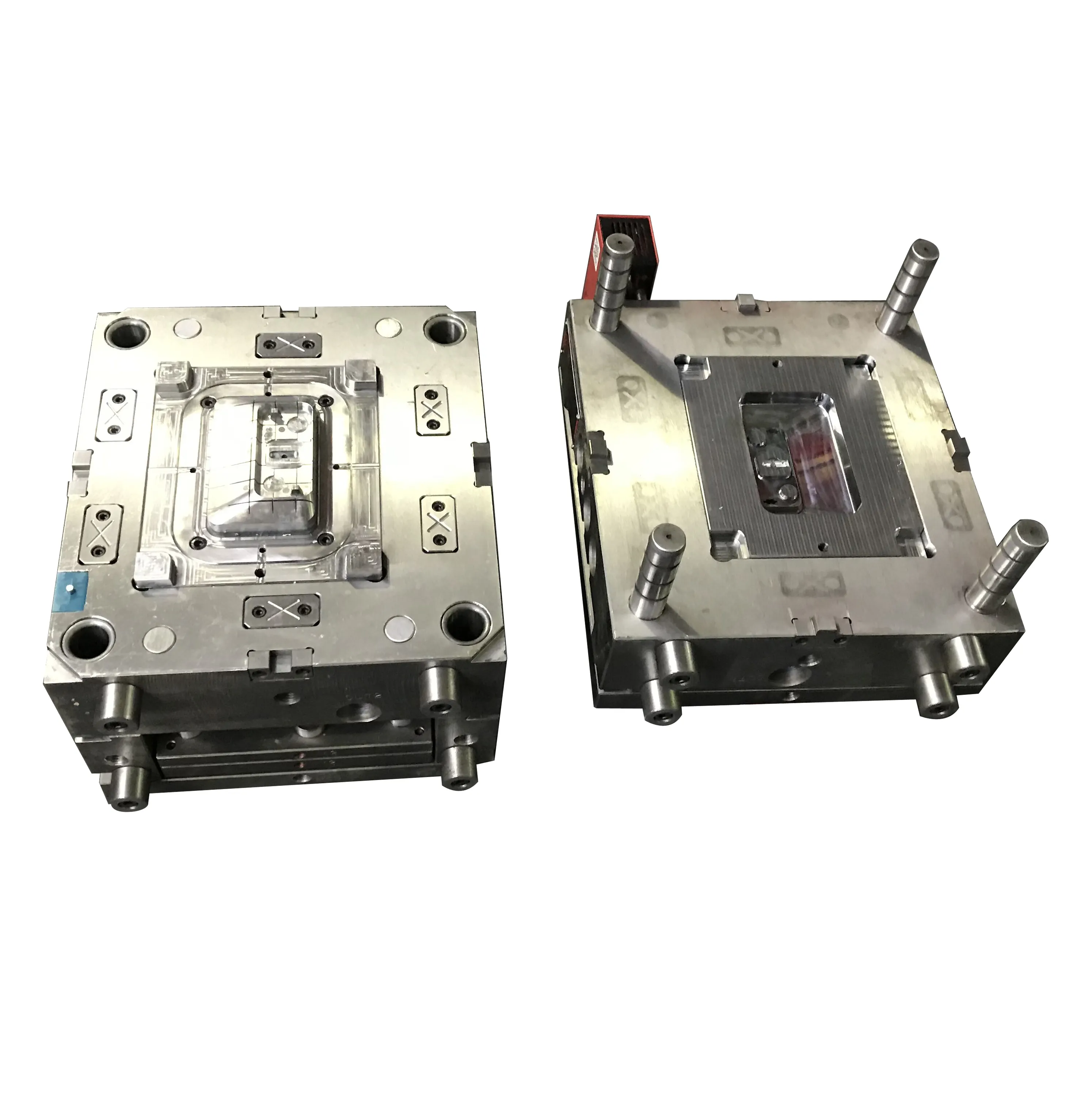

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.