Modern plastic part manufacturing relies on injection molding as a powerful method to form virtually any type of product. It is a method used by many factories to produce toys, containers, and even car parts. Part of this process is called the mold, and it is a very important part. The mold is used to take hot, melted plastic and put it in its final shape. The mold is a huge part of the integrity of the plastic items. Even if you know how to do plastic injection molding, this process is useless when the mold parts are of poor quality. That’s where Moldie comes in!

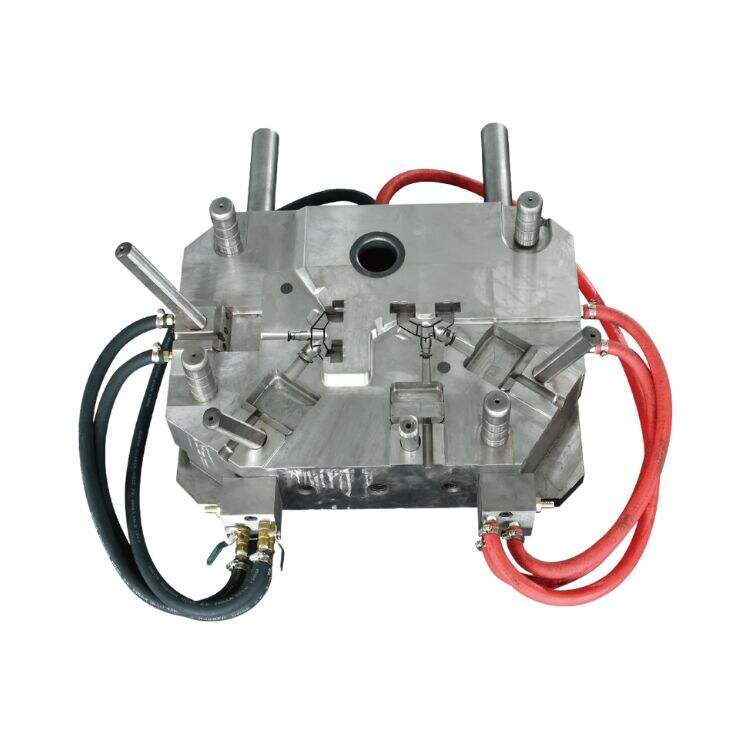

Moldie specializes in high-quality mold parts for injection molds to facilitate the injection molding process. †There are multiple components to the mold, and they all need to cooperate. So each part has its own responsibility and if something is not working right in one part, then the mold might not work perfectly. This can cause issues such as items not shaping properly, or even the mold breaking. For this reason, it is extremely important to use good, reliable, long-lasting mold parts. Having good quality mold parts assures you of proper injection molding.

Time is of the essence in the manufacturing world. Factories want to produce as many products as possible in as little time. It is why the use of precision-made parts for mold is very essential. Precision means that the parts are created with great care to be precisely the right size and shape. Accurate components assist the mold operate improved whilst lowering faults or troubles. This means that the production process can accelerate, and factories save time and money. When the supply chain functions efficiently, it allows us to satisfy customer demand for rapid product purchase and delivery.

Injection molding is a difficult process to get good results from. If the mold parts are not up to mark there are numerous things that go south. However, in order to achieve the desired level of outcome and the quality of your products; it is a good idea to rely on professional mold parts such as Moldie. Moldie's engineers and designers labor to manufacture functional and frugal parts. They know exactly which to keep handy to make the mold breathable and work perfectly. They will make sure that your production is good and that your products are of good quality.

One of the major advantages of high quality mold parts is that it promotes continuous operation. Having consistent mold parts means you spend less time trying to troubleshoot and fix things. There might be a lot of delays if the mold breaks or doesn't work. These delays can be costly and may limit the ability to keep customers satisfied. With the reliable mold parts provided by Moldie, your production line will continue to run smoothly. You will be able to concentrate on building more products and serving your customers.

Last but not the least, cycling the higher grade mold parts from Moldie means your plastic injection molding machines run longer and more efficiently. Good mold parts stick together better and last longer than bad ones. When you take care of your machine it can save you money over time as you won’t have to replace parts as often. In addition, using quality parts keeps your machines running properly, which causes your products to come out better quality as well. When your products are properly made, it enables you to work more efficiently and to build a good reputation for your enterprise.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.