Companies a lot of products are used by people in day to day life manufacturing is a great process by which humans are producing many products. Die cast parts are a special part of manufacturing. Different types of materials are used to create these parts which are used for multiple purposes. We will understanding more about what precisely are die cast injection parts, how can they be casted and what role do they play in the making of the product that individuals use and depend in their lives

Die cast parts come in a variety of types and sizes too. It means that the physical parts used in a product can be tailored perfectly to the needs of that product by manufacturers. This means that everything fits together just right. Die cast injection part can also be finished by painting or coating them, hence may also be shiny. It also provides products with a professional and good appearance to their customers

In numerous industries, there are guidelines and norms that need to be adhered to for ensuring that the products are safe to use and also high in quality. Add these standards for safety and die cast molded parts are essential to make sure manufacturers meet these critical safety standards. When one takes the case of the automotive industry, there are stringent regulations placed that ensures certain parts like the engine components and body panels are very robust and tough. Die cast parts allow manufacturers to produce products that match these demanding specifications.

Then, hot liquid metal is poured into the machine and injected into the metal high temp under pressure. The pressure is what helps make sure that the metal reaches every corner of the mold and creates a highly precise and detailed part. Afterwards, once the metal solidifies and cools, the form is opened and the part is gently removed. The part is cleaned and inspected to ensure we’re meeting quality standards. Finishing is optional, but can be done as well to improve esthetic.

Die cast parts have a wide range of usages, one of the biggest perks. They can themselves be made in a broad range of shapes and sizes, and they too can be finished in a variety of ways. For this reason, die cast parts are found in a wide range of applications. For example, die cast parts can be found in everything from kitchen appliances to power tools, medical devices to musical instruments.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

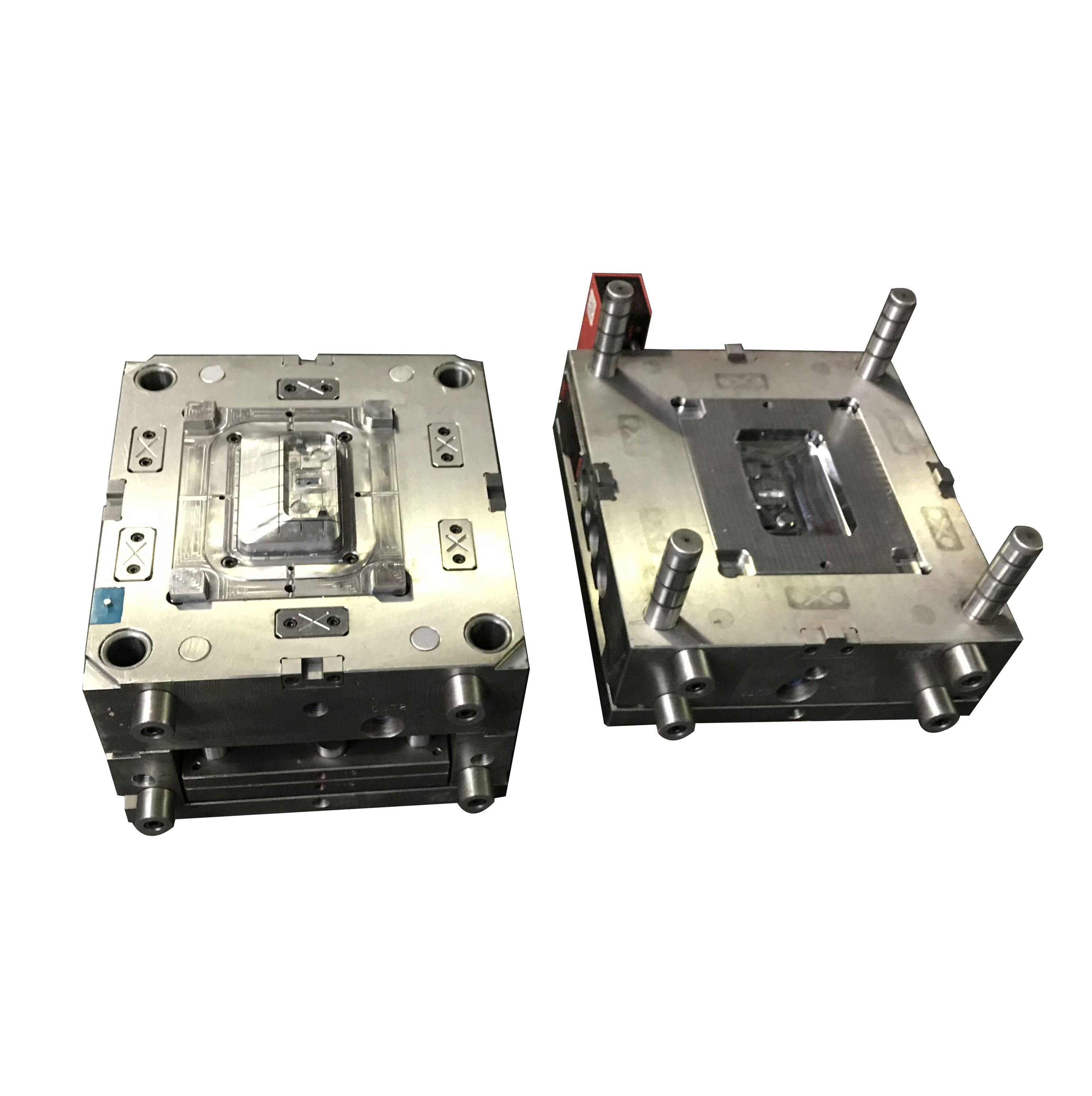

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.