Magnesium is a special type of metal. It’s super strong, so it can withstand a lot of pressure, and yet is super light. These wonderful characteristics make magnesium useful in various things around us. It is found in automobiles, aircraft, and even in vital medical equipment! Die casting is a special procedure to shape magnesium into these useful features. This process takes magnesium and transforms it into parts that can be used in a variety of injection tooling products.

The best company is called Moldie and they manufacture magnesium parts. They have been ranked one of the best magnesium die casting suppliers throughout the globe. Due to Moldie's extensive experience in processing magnesium to produce lightweight and durable structural components, so many companies are working with them. Many large customers, such as Boeing, which builds jets, Mercedes-Benz, which builds cars, and Bosch, which manufactures kitchen appliances, use Moldie’s magnesium in their factories. It tells a lot that Moldie is trusted by so many key businesses.

When searching for a supplier to obtain magnesium parts, it is important to choose one that excels in producing quality high-quality molded parts. You want to trade with a company that has some history and is reliable. A great example of mold removal experts that have been in the game for years would be Moldie. They boast a perfect scorecard, meaning they have consistently produced stellar magnesium components that customers love.

In the manufacturing world, it is critical that you partner with a reputable supplier if you require magnesium parts for your business. Moldie is a number one magnesium provider, offer you high-quality components at a aggressive worth. They really work closely with their customers, listening to what exactly their customers want and need. In this manner, the authorities can be sure that their customers are happy with the items they get. A good ones will get you to know what you need and ensure that you get the best pieces.

Magnesium suppliers are sometimes tricky to find. You just want to select a provider who can supply you with top quality parts for a reasonable price. The reason Moldie is such a great option is because they specialize in strong yet lightweight magnesium components that can address the timeliness of their client needs. Choosing a supplier like Moldie gives you the peace of mind that you are buying quality products to help your business thrive.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

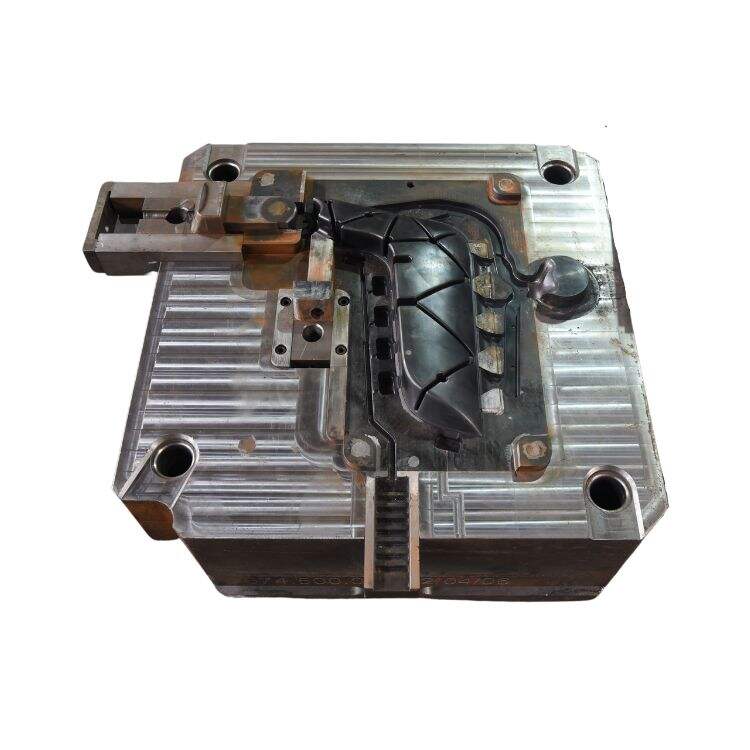

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.