Hello, readers! Interested in ? What are they, and how are they used in common things? Molded parts are crucial parts of so much of what we come into contact with; toys, cars, and even airplanes! So, in this article, we are going to give you an introduction to molded parts. Along the way you will also learn some new words! Moldie is our friend, so let's start with him!

Ever heard of the word "precision"? It means that something is created in a very careful and perfectly once. This is super important for molded parts, especially those in cars and airplanes! These machines are benefitting from molded parts that allow them to function as intended.

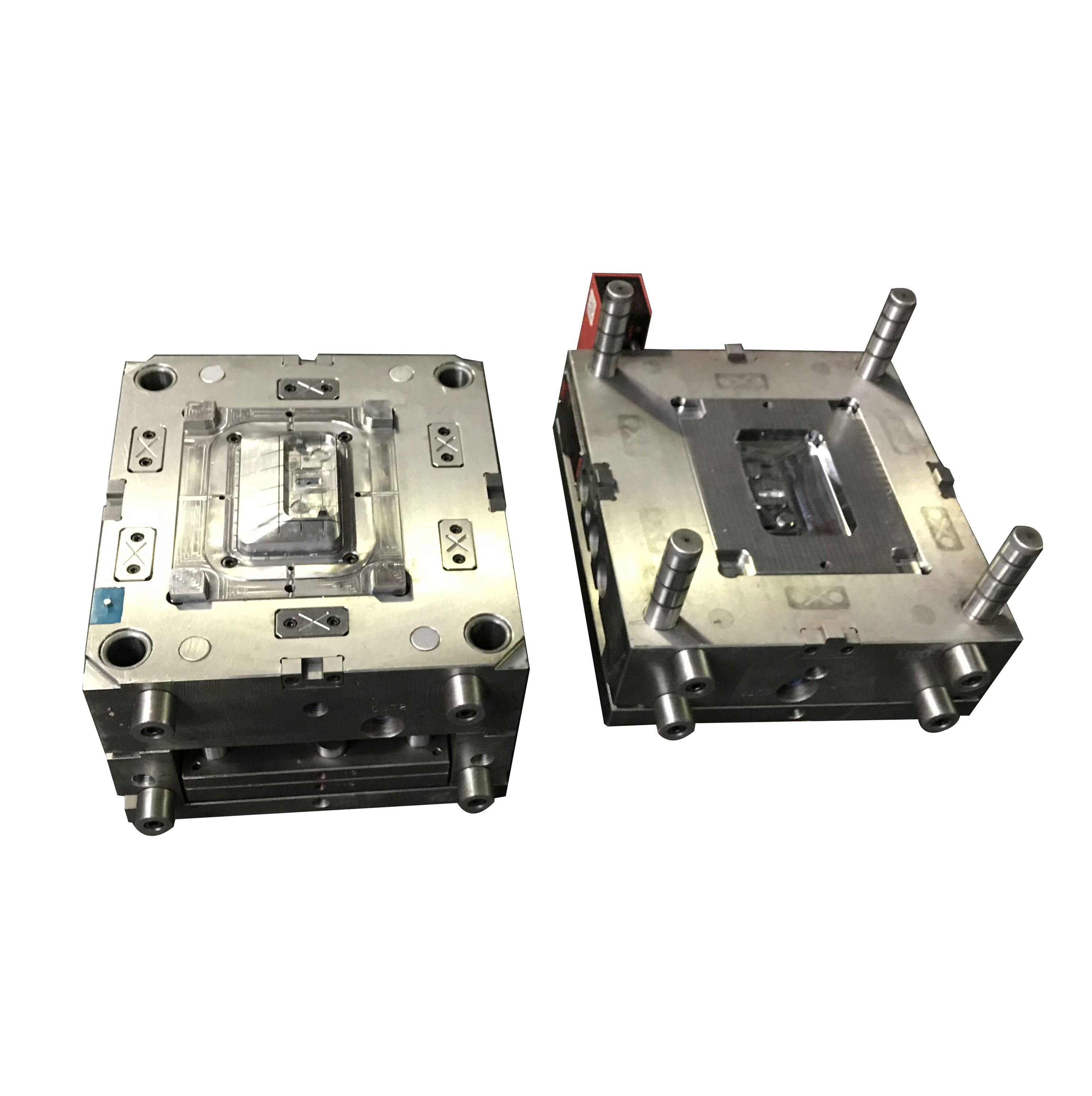

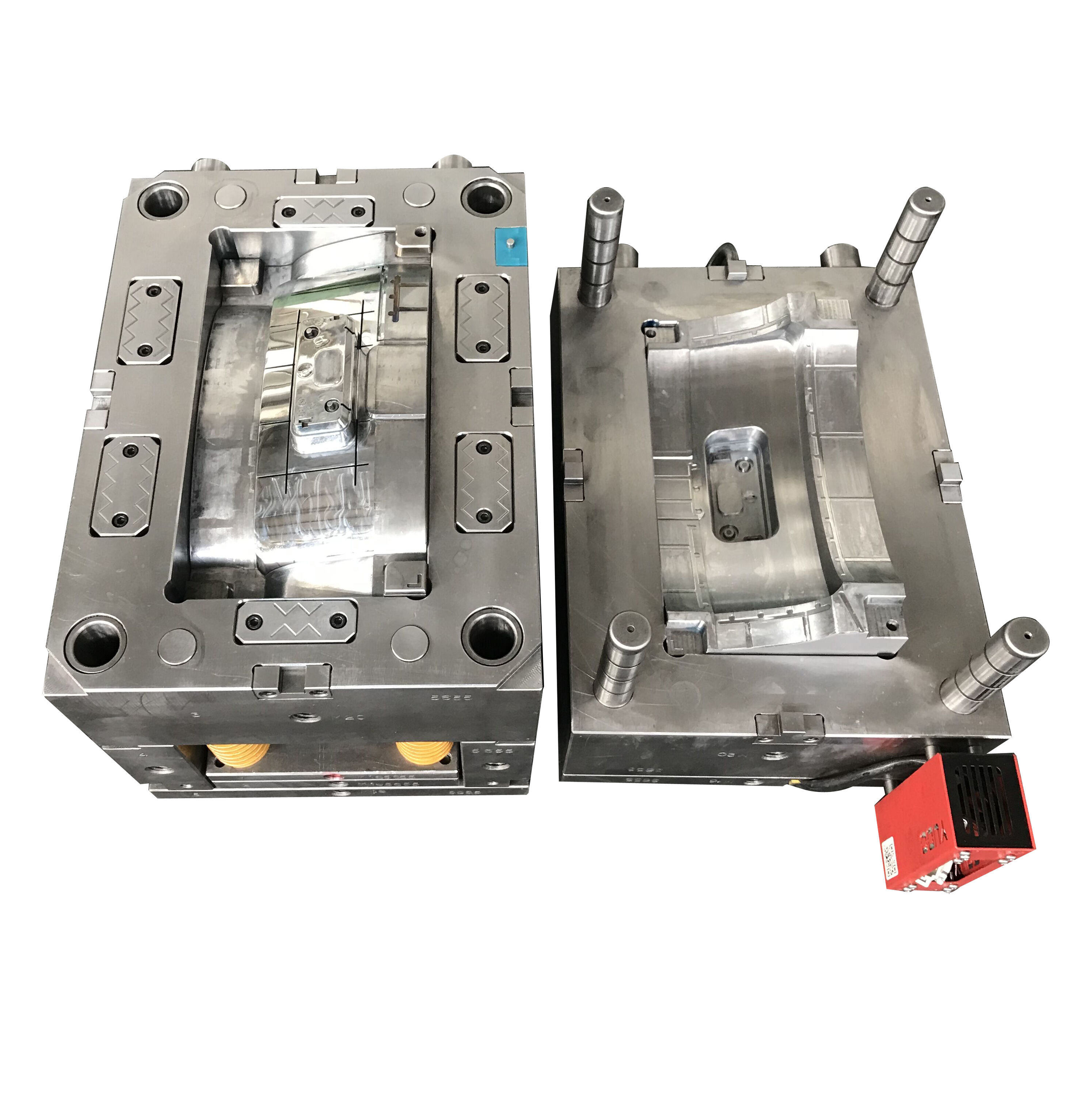

They are manufactured using a special process called injection molding. This is when melted plastic is injected into a mold, which is basically a shape or a container. Then, the melted plastic is cooled to solidifyate it so that it retains its shape. Moldie focuses a lot of attention on ensuring that all the molded parts they produce are highly manufactured. This means that when parts are produced, they align perfectly with the machines they were intended for. Its all about making sure everything fits just right, letting the machines work as their supposed to and return the favor with longer life!

Molded parts are made of hard plastic and can withstand extreme pressure. So, this is why when Moldie is molding parts, it follows a process of selecting the right material and processes that ensures the durability of the product. Especially with car parts, as you wouldn’t want your car to function poorly or break down on the road when going on your summer road trip! No one wants to end up on the side of the road, right?

The term "customized" is a special word used to mean something that is made every you or for someone else specific needs. Moldie knows that every machine and company is a bit different, so there is no such thing as a one-size-fits-all solution to molded parts. Moldie’s molded parts can be tailored to specific needs, and that’s a big part of its transformative power.

Another keyword is: “Cost-effective.” It says that something is not very expensive, you are getting good value for money for the product/service. Moldie understands companies want the most bang for their buck when they spend money. That is why they ensure their molded parts are low-cost and high-quality.

As an example, Moldie employs technology using 3D printing to create molds. So that means they can create very, very precise shapes and patterns. Additionally, they have advanced composites where the specifics pass into the inner materials making their molded parts durable and robust. Moldie maintains the very latest technology for making sure their products are nothing less than the best. This is the only way to make the best molded parts for everyone!

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.