Aluminum is special type of metal; metallic aluminium is very thinner, can be used for multiple purposes. It is also in cans, cars, and in airplanes. Aluminum must be melted to create various shapes and designs. achieved by pouring the melted Aluminum into molds. This whole process is referred to as Aluminum casting. Pour the hot Aluminum, melted Aluminum into the mold, and let it cool down over time, it will harden in the shape we want.

Melting Aluminum is not a thing you just do, it takes some practice, the same as Moldie's aluminum casting molds. We melt Aluminum using a furnace (a hot oven made for melting metals). The Aluminum will melt into a liquid when it gets hot enough. Then we can dump that Aluminum into a crucible. A crucible capable of holding molten Aluminum safely. We wait a while after pouring it into the mold. We can then allow the Aluminum to cool completely, and then remove the mold which now should be a nice shape.

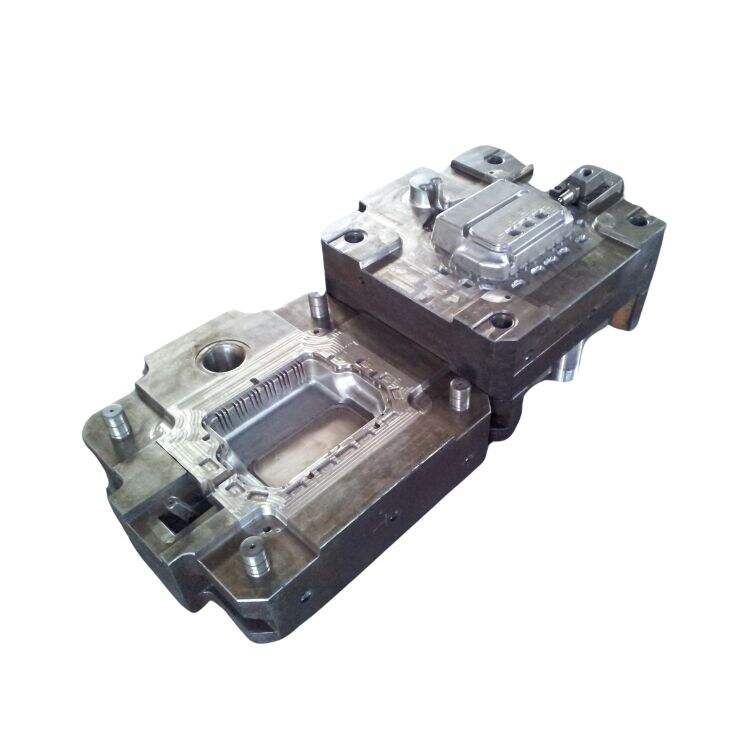

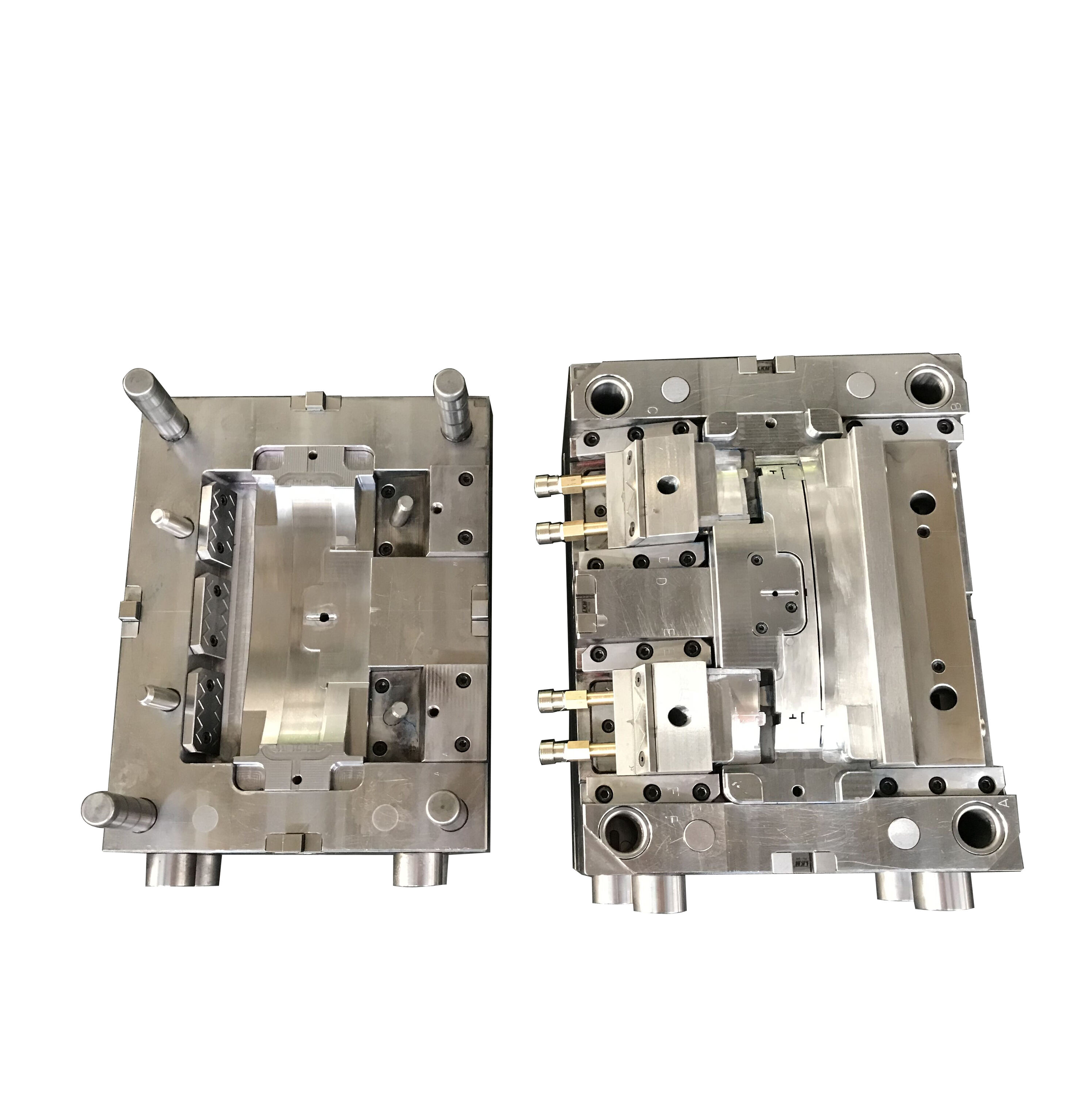

Use a good mold: The mold that you use is essential, also the aluminum die casting built by Moldie. The final Aluminum shape will have its own precision, and a suitably good mold is key to making sure you get it right. It cradles the hot Aluminum while it rapidly cools, ensuring everything comes out correctly.

Use the right amount of Aluminum: You need to make sure you’re using the right amount of Aluminum for your project. If you use too little, your shape may be weak or break easily. On the flip side, too much Aluminum and it’s impossible to manage — you end up with the wrong shape.

Cool it down: Filling the empty space lets the Aluminum cool quickly, and that changes how the final shape will look, similar to the Moldie's product like welding cast aluminum. If the Aluminum is cooled slowly, it will have a smooth surface, which is a good thing, but it might take a long time to cool completely. If it cools faster, it may have a rougher surface, but the advantage is that it will cool faster then.

Long-lasting :Another thing is that Aluminum is also a very strong and durable material, along with the sand casting aluminum produced by Moldie. Being extremely durable, it can withstand both varying temperatures and weather conditions, which ensures it will not only look good over the long term but also last quite a while as well.

Used Aluminum is one of those methods, just like the Moldie's product called aluminum casting alloys. This is a good thing because recycling Aluminum requires less energy to melt than new Aluminum. Recycling Aluminum also results in less waste produced during the manufacturing process, making it an environmentally friendly option. Because recycled Aluminum has already gone through a processing phase, it does not require as much energy to turn it into a product.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.