Moldie is a fun company and they make all sorts of cool stuff that jpeople love. They make toys, phone cases, and countless other products that we interact with daily. Moldie uses a very specific technique called LSR injection molding, to create all of these crazy cool items quickly and easily.

LSR injection molding is a special process that allows companies like Moldie to produce large volumes of products quickly. Well, they use this rubber called LSR, or Liquid Silicone Rubber. The initial step is heating the LSR to a high, flowing temperature. Then, this hot liquid is poured into a mold. A mold is like a shape that creates the final product — you know, like a cookie cutter. After the LSR has filled the mold, it cools and becomes solid. So Moldie can make lots of the same product at once! This is ideal for items -- toys, phone cases, etc. -- that everybody wants in mass quantity because really, who doesn't like having the same thing?

LSR injection molding has its applications and many advantages. It is very accurate which is one of the major advantages. Every product ends up looking and functioning the way the others do. This is super important to companies that want their products to be the best they can possibly be, like Moldie, so that they work the way they should for anyone who buys them. The other best thing about LSR injection molding is that it is highly efficient. Efficiency is what Moldie is known for, being able to produce many products quickly and with little time or materials wasted. This enables them to stay in line with their customers’ expectations. In addition, LSR injection molding is also eco-friendly. Moldie really loves our Earth and so wants to use methods that help keep it safe and clean. This makes using LSR injection molding a very logical choice for them and something that keeps them responsible while producing products.

With LSR injection molding, Moldie can manufacture very quickly. This speed-to-market in production helps them to get their products to market ahead of other companies. Not to mention that people are always on the hunt for the new and best products available on the market! The training is up to October 2023. It helps them to stay updated with trends and be a customer-favorite.

The other critical fact about LSR injection molding is that it is an eco-friendly answer for producing articles. Sustainable means it is good for the environment and does not harm our planet. Moldie aspires to be an Earth-minding company. It leaves very little waste when they use LSR injection molding, meaning not much extra material will end up in the trash. And, the elements used in this process are recyclable, which allows future products to be made with the same materials. With this innovative technology, Moldie is doing its part to maintain a clean and healthful environment for all of us on the planet.

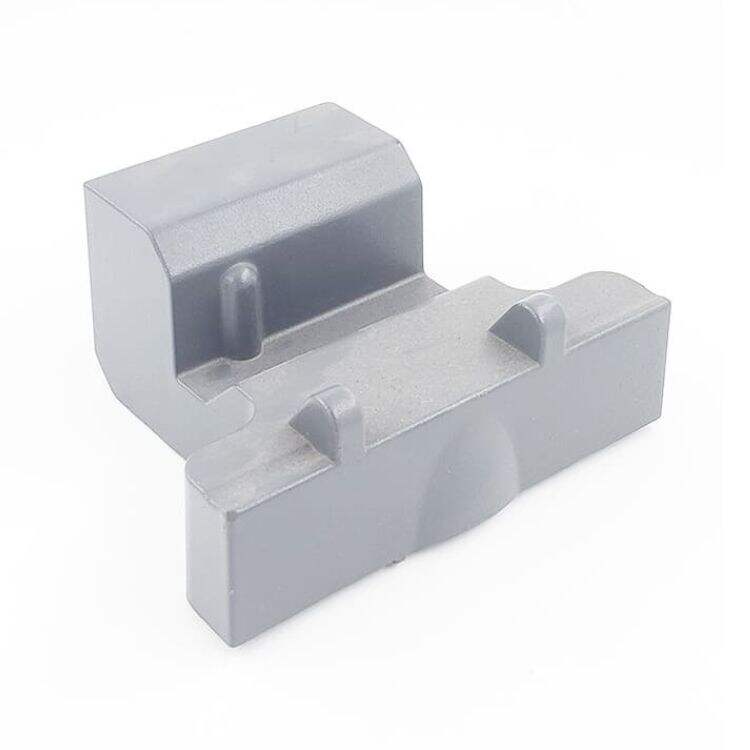

Last but not least, LSR injection molding is excellent for making a great range of items. For example, it can produce people’s baby bottle nipples, toothbrushes, phone cases, and parts for a car. Thanks to LSR injection molding, Moldie can produce a wide range of products for a variety of industries. This is great because it means they can be a jack of all trades, serving the needs of both customer segments.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

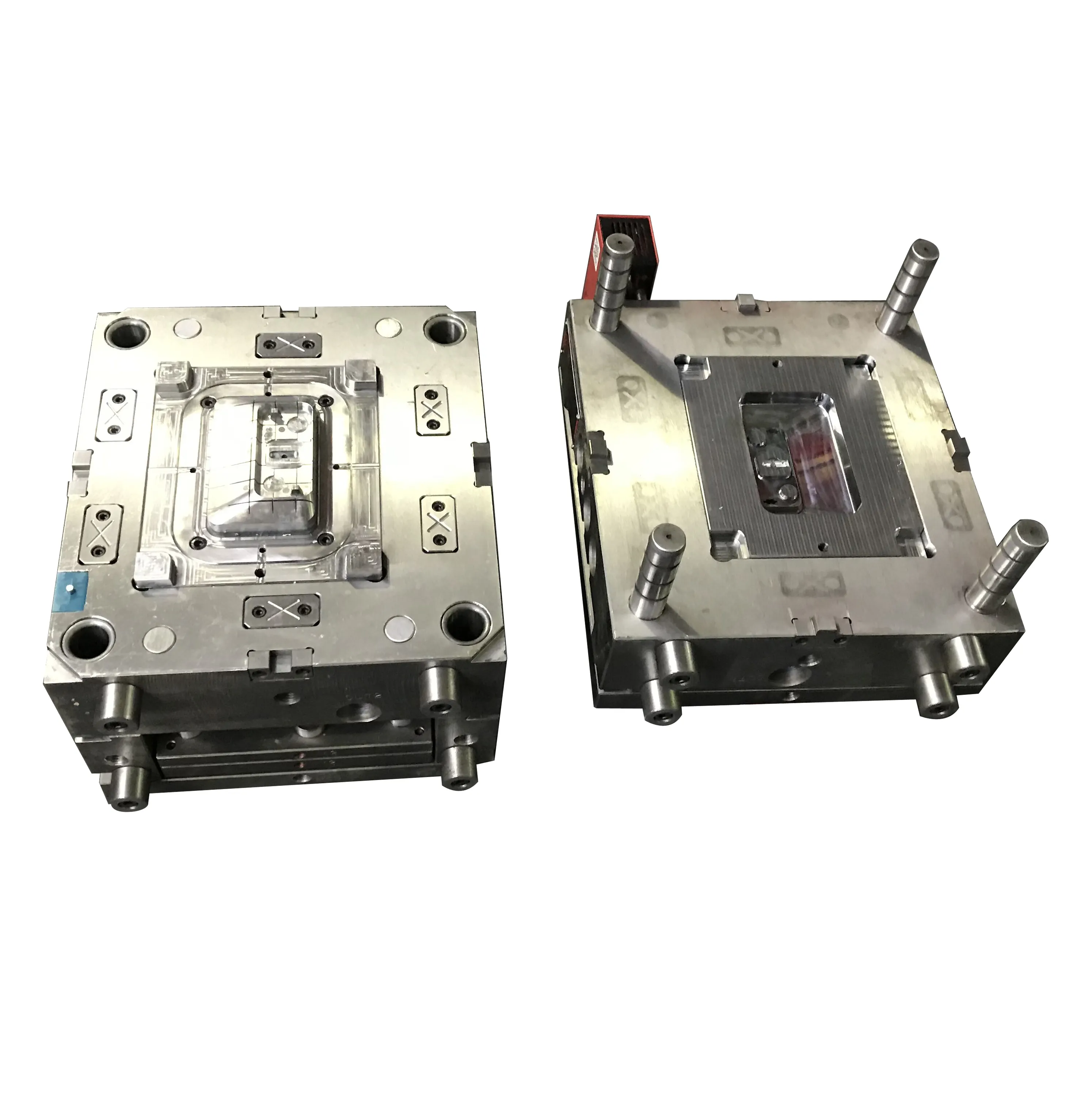

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.