Casting is a special method of forming shapes by pouring a liquid into a mold. You may think it sounds complicated but Die Pro Cast does it all, simply and entertainment, same with the aluminum die casting. You can melt multiple types of metals to create shapes and objects, including Aluminum, copper and brass. These materials are powerful and can be formed into beautiful things.

If you want to be able to cast something, there are a few crucial steps to follow in order for you to be successful. You have to melt the metal first, so it is liquid. After that, you take the melted metal and pour it into a mold, which is a container that gives the melted metal that shape you want it to be. Afterward, you allow it to cool and set. If you are making a great cast, you will check the temperature of the metal, the quality of the mold, and the way you pour the metal. These accounts have very crucial specifics. If only there was a golden way to have an overview of these details and make casting so straight-forward and fun. Well, fortunately, you are in the right place because Moldie Die Pro Cast as well as aluminium pressure die casting is here to help you with your casting all time easier.

It’s a good idea to think about what kind of mold you want to make before you start casting. It might be something simple, like a keychain, or something a little more complicated, like a cool sculpture. With Moldie Die Pro Cast and aluminium gravity die casting, everything you imagine is possible. This begins with a mold, which is formed from a pattern. This pattern can be made from various materials such as wood, wax, or a 3D printed form. It is like making a draft of your project. Now that you have your mold, you can melt the metal and pour the molten metal into your casting mold.

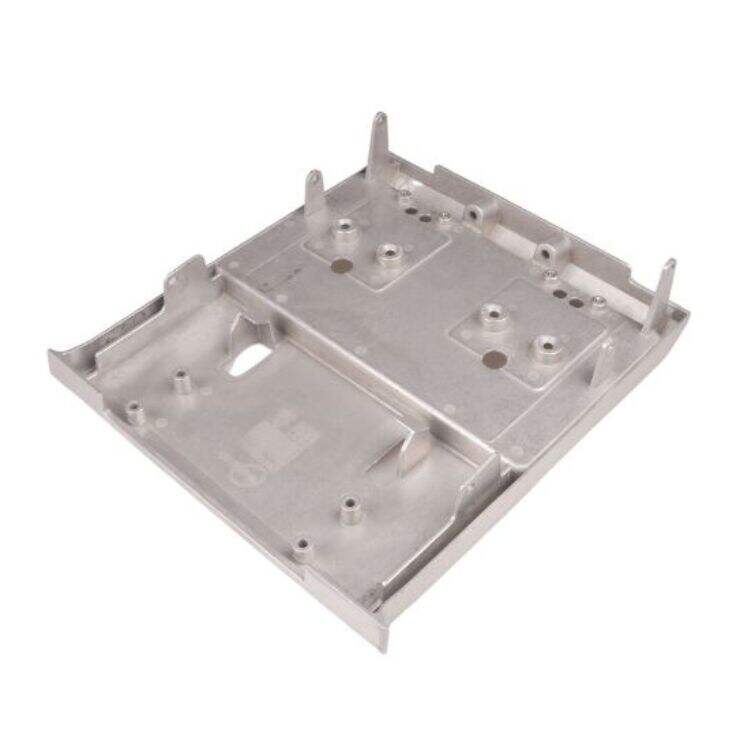

The particular metal types and pouring qualities from Die Pro Cast have the best characteristics for casting. Aluminum, copper and brass are great to work with and are pretty much gimmees. Metals have unique properties and can be made into all sorts of things. Die Pro Cast's top-notch metal and super smooth finish make it easier to get a good casting and not make any mistakes.

Casting is a fantastic process, and you can create anything, large or small. Create beautiful jewelry, useful car parts and artistic sculptures using Die Pro Cast. It’s also a nifty money saver as you can DIY instead of buy. Then, you have the pleasure of having done it yourself. But with practice over time, you will become a casting pro, and impress all your friends and family with your new-found casting skills.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.