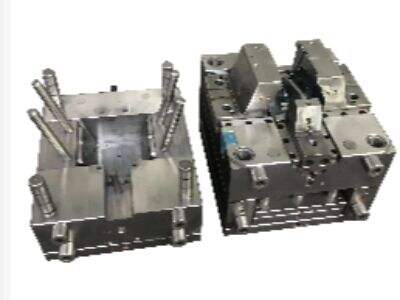

Injection moulding revolutionizes how we make things today, allowing for a faster and more cost-effective way to manufacture thousands of products. High Precision: Injection Molding is capable of producing extremely intricate shapes very accurately. This process requires PPC to melt plastic pellets and inject them into a mould in the final shape. Now we are going to explore just how injection moulding is revolutionising the way things are made.

Wholesale Opportunities in Injection Moulding

The process of injection moulding represents a whole new world of wholesale possibilities for anyone wishing to manufacture quantities of products in bulk. Companies are able to make loads of things, such as toys, car parts and packaging materials fast and cheaply with injection moulding. This mass production capacity enables companies to satisfy the market needs effectively and be competitive. For instance, a toy manufacturer might use compression moulding to produce thousands of identical parts in a very short period of time, which will be required by retailers. For all these reasons, injection moulding is a very popular wholesale manufacturing option.

High quality injection moulding Services

When you are seeking quality injection moulding services, you should also consider the manufacturer’s capabilities in terms of the production output and technology. If you're looking for such a company, moldie are experts in injection moulding and implement the full spectrum of services from design support to prototyping to production. Working with a reputable company, can give businesses the confidence that their products are made at the highest quality and get delivered on time. Companies such as moldie will also make use of the newest technology and manufacturing equipment to optimize our injection moulding process, so that it is faster at turning out products, and ensures a higher quality end product. Selecting an ideal injection moulding service provider can make a world of difference between businesses in terms of catering to their production needs and providing quality products.

Influence of the injection moulding on product quality

Injection Moulding is a manufacturing process that has drastically changed how products can be mass-produced. Manufacturers can form products with high precision and uniformity by molding molten materials into a desired shape. This enables the creation of complex shapes and details that would otherwise be hard or impossible to fabricate using other techniques. Products made from injection moulding are often of excellent quality and durability.

Injection moulding is beneficial by its ability to manufacture items in close tolerances. This implies final items are in very high precision and uniformity. It is particularly critical for products where tight tolerances are essential, such as line-items of electronic components or medical devices. The injection moulding also permits a variety of materials such as plastic, metals and ceramics to be used which will enhance the quality and function of the end products.

On the whole, injection moulding has greatly affected product quality in today's industry. This has allowed production of high-quality products with tight tolerances and complex shapes, which is essential in satisfying the demands of competitive markets today.

Injection Moulding – How The Process Can Be Used In Many Industries

The injection moulding is a flexible process and it’s mastered by different industries. Plastic parts and components are among the most widely produced through injection moulding. This encompasses everything from domestic products such as toys and kitchen utensils to industrial components including car parts and medical devices. In the electronics industry, custom plastic injection moulding can be used to mass-produce components for cell phones, computers, and other devices.

Besides plastic it can also be used for any other material such as metal, ceramic. This is being routinely used in automotive and aerospace for making high performance parts requiring strength and reliability. Consumer goods are also produced using injection molding, including containers and furniture.

In general, the injection moulding process is versatile in any application to use and is a real asset in multiple sectors. Its excellent material properties make it an indispensable tool for modern manufacturing creating products in even shorter time with higher quality.

Things to Consider When Selecting an Injection Moulding Partner

When deciding on an injection moulding supplier there are a few points to work your way through so you get the right product at the best price suitable for you. One of the key aspects you should look for in a supplier is their pp injection moulding experience and knowledge. Trust your supplier to get it right An established, reliable supplier who has delivered the goods – literally – in terms of top-notch product is more likely to make what you need and deliver it as per your expectations.

Also of importance is the ability and resource of the supplier. Ensure the provider has the equipment and technology required to make what you require. That also includes the flexibility to handle a wide range of materials and form intricate shapes and designs. You should also look at the suppliers capacity and lead times to guarantee that they can keep pace with your production schedule.

Price is another important factor when opting for an injection moulding provider. Source multiple quotes and compare them to identify the most competitive bid available. But beware of suppliers that offer a much cheaper price, this may mean inferior products or poor manufacturing.

All things considered, selecting the best moulding injection company is critical to the success of your manufacturing efforts. Taking into account experience, skills, and the price on offer will enable you to locate a suitable provider that can aid you in consistently producing excellent products in as little time for as little cost as possible.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

HU

HU

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

IS

IS

HY

HY

AZ

AZ

KA

KA

BS

BS

LA

LA

KY

KY