If you've ever used a plastic product, chances are it's made with a process known as . PP=pollipropylene=one type of plastic. It is a very tough, lightweight, and inexpensive type of plastic. PP injection is a process where the plastic is melted and injected into a mold to shape it into a desired form. Many different kinds of plastic products are made this way, such as toys, containers, and parts used in cars.

Perhaps the most important reason to opt for PP injection is that it can save your company time and costs. Molding of plastic is a very fast process when the plastic is melted and injected into a mold. A considerable amount of products can be generated in a small interval of time. So, let's say a factory has to produce a lot of toy cars. In addition, the raw materials required for this process are relatively cheap. To manufacturers, this means PP injection can be a cost-effective option, and therefore can be cost-effective while producing quality products.

Strength and durability are critical in plastic products. One of the best methods for creating long-lasting products is PP injection. This polypropylene plastic possesses unique properties, allowing this material to resist many chemicals and other materials. This is very helpful for products that may come in contact with things that would cause damage. Is there a specific use case for any use container: containers for cleaning need to be resistant to different chemicals and strong? Additionally, PP injection has an advantage for consumers in that products made through PP injection can be light and easy to carry.

PP injection allows companies to specialize and create different designs and shapes for their goods, which is another fantastic feature of PP injection. Because the plastic gets melted down and injected into a mold, it can be molded to any shape or size that is required. This means that companies can produce one-of-a-kind and personalized products that are made exclusively for them. So, for example, if a company wanted to make a toy that was a special item shaped like their favorite Character, they can use this process to do it. Also, since the PP injection process is relatively quick and efficient, it is easy for companies to adapt if they need to do so without slowing things down or being hit by higher costs.

It is a good approach to go with PP injection if you require plastic goods. Moldie specializes in PP injection high-quality services with custom capabilities to provide solutions for your individual engineering requirements. Additionally, our team of professionals can collaborate with you to develop a design that is functional as well as aesthetic. Because when you invest with us, we want it to last and be as cost-effective as possible.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

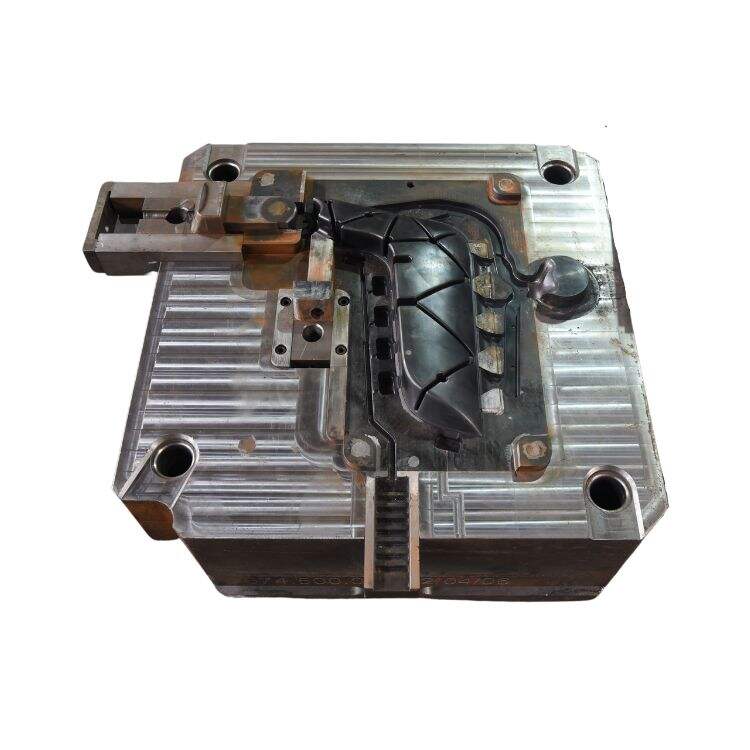

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.