Moldie is a popular Chinese company that manufactures metal parts and offer quality services. They employ a particular process called die casting. Die casting is a process where metal is casted by melting down the metal and pouring it into a mold called the die. This allows you to build very complex parts with lots of complex geometry. The team at Moldie is extremely proud of the work they do and are committed to ensuring customers get exactly what they are looking for.

Moldie makes sure they are working with metal components that their clients need and that their metal parts meet the desired standard which is just so much of an infallible part of the process. The die casting companies specialize in providing high-quality products that cater to particular requirements. To do that, Moldie uses state-of-the-art electronics and machinery which aid in the production of quality products. They're detail-oriented and know precision is everything in their industry.

Moldie is constantly seeking to expand our toolbox with innovative approaches to solve difficult die casting problems. They provide a variety of services to assist their clients. These services cover everything from part design, engineering and even prototype modeling. A prototype is an earlier version of a product that demonstrates what the final product will look like. Moldie's engineers are really focused on every stage of a project, from the initial concept to the finished product.

Moldie employs two principles of the die casting process: hot-chamber and cold-chamber methods. The method is especially beneficial for metals such as zinc and magnesium that can be melted and then cast easily. However, the cold-chamber process is better suited for metals such as aluminum and copper. With these two techniques, Moldie is capable of making parts both very precise and of the finest quality, meeting the demands of their customers.

Moldie has purchased cutting-edge machinery and technology planted to fully cater to the various demands and requests of their customers. They know that the right tools will make their lives easier and more productive. They have some amazing machines, including a a fully automated casting machine. In these machines, die casting products are produced very fast while also being checked for quality during production.

Upon completing the production of the metal components, die casting suppliers like Moldie also provides additional services that improve the products even more. These post-processing services can obtain CNC machining, powder coating, anodizing, etc. As a result, customers can pick and choose coatings and finishes that help improve their parts visually, but also their durability and function as well.

With a focus on quality, innovation, and customer satisfaction, Moldie has become a trusted and reliable partner in the international die casting market. Their services cater to a wide array of industries such as automotive, aerospace, electronics, and home appliances. This diverse set of skills indicates that Moldie can cater to the requirements of different industries.

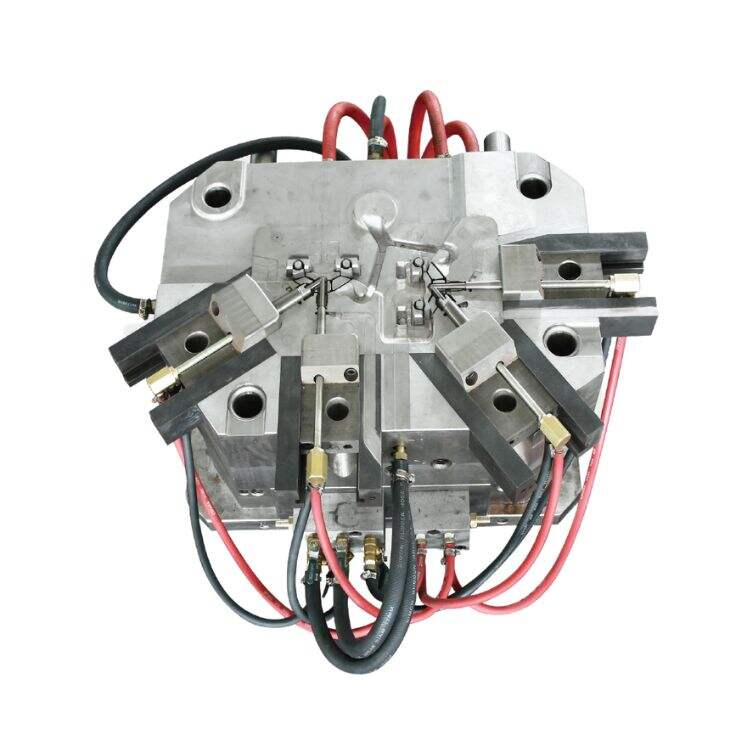

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.