One method we utilize to produce such things as cups, lids, toys, and components found in vehicles is plastic molding. This approach is excellent as it allows us to create many of the same items in a very quick and simple fashion. It is a little like a magic tool, where you are able to create a ton of identical items without much of a problem. Plus, this method is quite economical, so it is not as expensive as some of the other means of creating things. This is vital to our business and allows us to maintain price competitiveness for our customers.

Polystyrene injection molding may seem like a potentially difficult way to make things, but it’s pretty by the book! First, we take small balls of polystyrene plastic, and we heat them up until they melt and become a liquid. This is similar to melting chocolate to create delicious something! Once the plastic has melted, that liquid plastic is then injected into a mold. Next, we have mold — this is a unique shape that we want the object to resemble, similar to a cookie cutter. After pouring the liquid plastic into the mold, we let it cool for a couple of minutes. Once it has cooled we can pull that from the mold. And now we have a new object available to use! This is so satisfying to view the end result!

If we use mold plastic injection, temperature and pressure have a significant impact on making everything as intended. And we have to heat that plastic at a very specific temperature, which is crucial. Too much heat to the plastic would weaken it or damage the mold we are using. Similar to overcooked chocolate left in the microwave, it will burn! On the other hand, if the plastic is too cool, it won’t flow easily and smoothly into the shape inside the mold, and that can ruin our desired shape.

Plus, we have to apply great pressure when pushing the plastic into the mould. That pressure ensures that the plastic completely fills every little nook and cranny of the mold. A properly filled mold equals a better finished product — it looks good and works as intended. So, temperature and pressure drive this process!

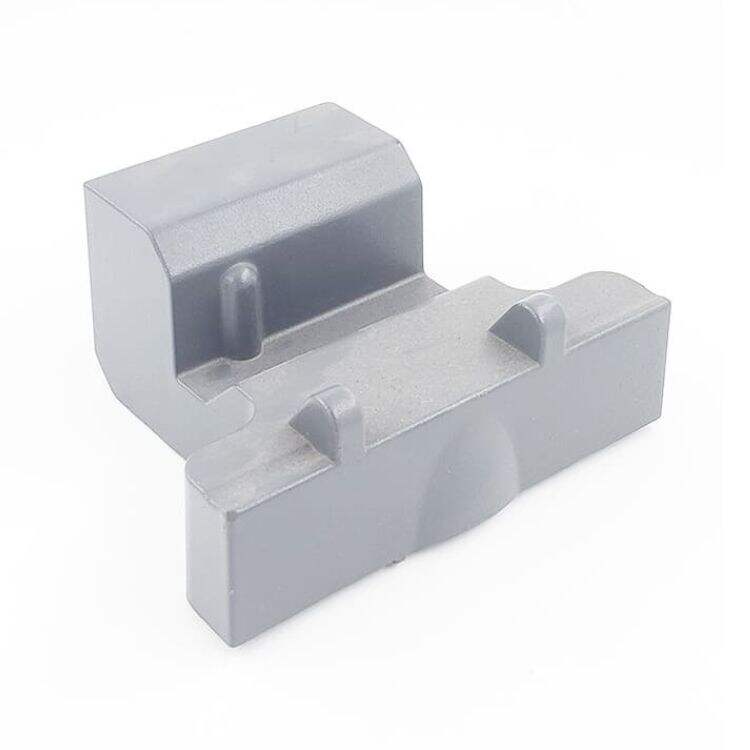

The design of the object and the mold plays a critical role in terms of the functionality of everything when we produce new objects using polystyrene injection molding. The design needs to be simple enough to create yet strong and functional. We want to make things that people can use and depend on! It requires a massive amount of accuracy and attention to detail to create the mold which defines the product. If the mold is not done right, the final product won't turn out to be of the right shape or function the way it should have.

The polystyrene injection molding process is not only a great means of making many identical objects, but it’s also an intelligent and green solution! We use only the necessary amount of plastic to create each object. It means we don’t waste a lot of material, which is good for the environment.” It’s kind of like not letting your food go to waste and eating everything on your plate.

This saves us time and resources because we can quickly produce high volumes of objects. Because of this efficiency, we can make so many products, as we are not wasting money or materials. So this way of working enables us to be responsible but still be able to make affordable stuff that people need and want.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.