Of all the manufacturing that we use in our day-to-day products, moldie die for plastic moulding is a rather unique method to produce plastic parts. They do this by taking small pieces of plastic — also known as pellets — and melting them down until they form a viscous hot liquid. The melted plastic is then forced into a mold. This mold acts like a kind of container that will help to shape the plastic into the specific part that we want. Once the plastic has cooled down and solidified, we remove the part from the mold. One example is how this technique is used to create a variety of devices that assist us on a regular basis.

Moldie is a company that specializes in creating these plastic components. It means to make efficient, they should also be work within no time and cost-effective means to keep the prices within limit and within customer's access. Moldie team uses specialized technology to guarantee every part is of high-class quality but also available at low and user friendly prices. It ensures that customers get the biggest bang for their buck when selecting Moldie as their provider of plastic parts.

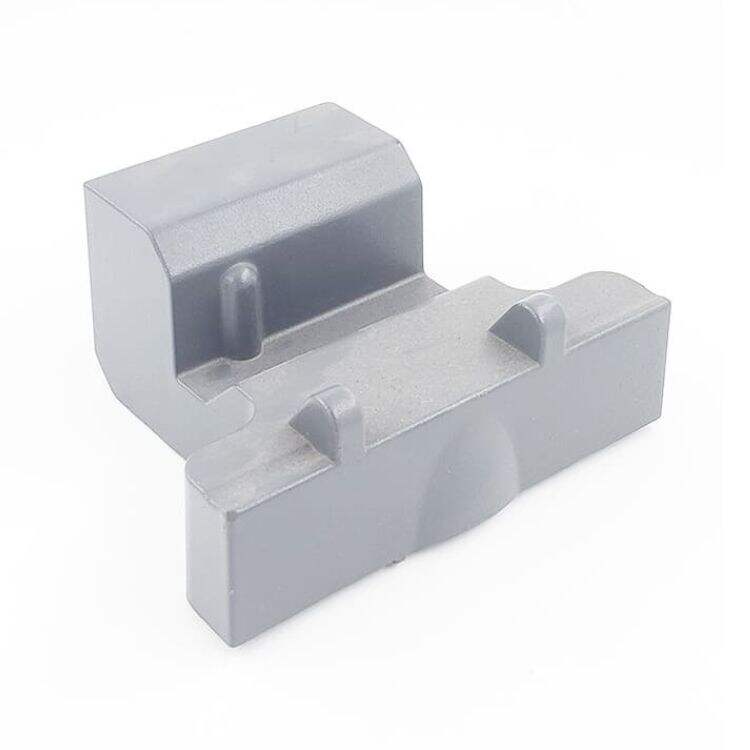

So plastic die casting is great for manufacturing strong and complex parts for any industry. Most moldie die cast aluminum alloys are almost totally used in automobiles in cars, medicine in medical instruments, and consumer’s electronics-the latter includes just phone and tablet. Moldie, additionally, has considerable experience of not only robust but also sophisticated components manufacture. Using the latest machinery, they guarantee that every part is manufactured correctly and according to the high expectations of their customers.

The Moldie team utilizes plastic die casting for the creation of products in a way that maximizes product design. Experts interact with the clients to understand what they want and what they need. It is that personalization that allows making custom parts, specific to them. This system of making different thickness of the parts according to requirement is the unique feature of moldie aluminum pressure die casting. They can also be used in adding different textures and colors that make each product not only more attractive but also more functional and useful for consumers. This creative method targets the customers looking for your exact product.

I strongly feel that Moldie is an environmentally conscious company, and it is well aware of the necessity to promote ecologically friendly production methodologies. They work toward reducing waste and conserving energy; these are important requirements in keeping our planet clean and healthy. Moldie attaches a big emphasis on utilizing recycled materials whenever this can be done. They also properly dispose of all sorts of waste materials, minimizing the effects on the environment. These attempts of Moldie demonstrate their support for the conservation of our Earth for our future generations.

All plastic parts are always made and tested so Moldie offers a warranty for all parts manufactured. The professional specialists carry out strict quality control checks to ensure that each moldie die casting alloys aluminum meets the highest quality standards before it goes out. This means that at Moldies team, everything is checked to ensure that the parts fit together well, have workable surfaces, and are not flawed. Commitment to excellence from Moldie ensures that the customer can always rely on them to provide products that meet high standards.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.