The world has some very strong materials that help us build many things. These materials go in to make cars and airplanes. The toughest of them all is magnesium alloy. It’s true. First Step of Magnesium Alloy- Overview Magnesium alloy is an alloy formed with magnesium and other metals. Moldie is a magnesium and aluminum die casting company. They know that powerful and sustained materials for customers are vital to guaranteeing products that are safe and long-lasting.

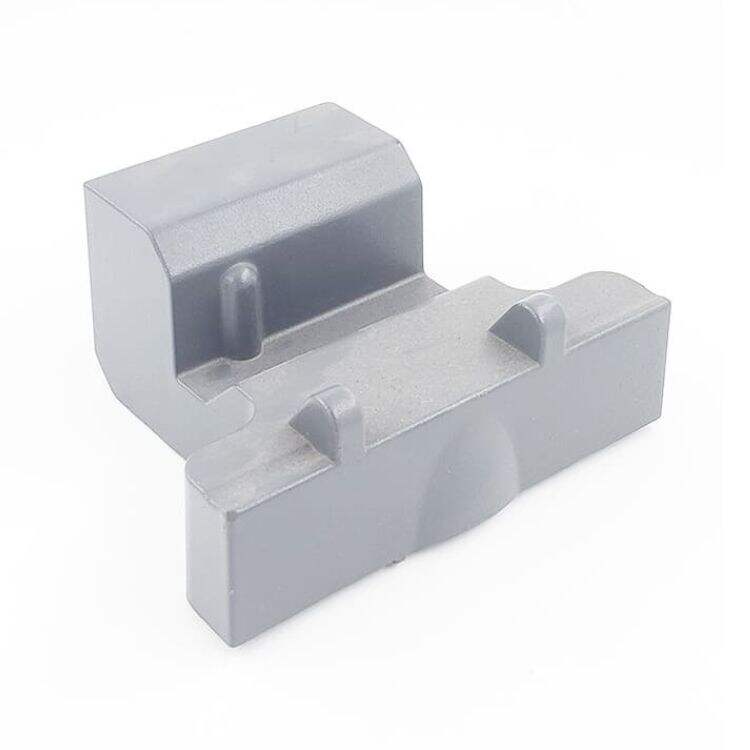

This makes magnesium very robust, and it is an excellent material. Magnesium is also extremely light weight. That means that magnesium-based goods are easier to lift and maneuver. In addition, magnesium is hard, meaning it can withstand wear and tear from extended use without breaking or damaging easily. Moldie magnesium alloy die casting is designed to be extremely durable and lasts for decades. For car components, this magnesium casting is particularly crucial, as they must endure frequent use and the stress of driving.

Besides zinc being the most common ingredient in die casting aluminum alloy is also very significant with respect to die casting. So aluminum is also a strong material but more importantly it was flexible. It’s malleable which means it can be formed and reformed in all kinds of ways and used in a wide range of products. Moldie produces a variety of items use aluminum alloy die casting including heat sinks LED lights even airplane parts. Through aluminium they can create original designs and manufacture interesting products which may be both very strong and highly functional in various different circumstances.

The great thing about magnesium as well as aluminum alloy is their highly versatile materials. This allows them to be used in various ways and to create many different types of products. One example of this is that Moldie can produce a small portion of an electronic device, where magnesium alloy die-casting is used. The magnesium die casting can also manufacture larger, complex parts for car engines. Being able to do so means Moldie can make a recipe for many different industries, which is very crucial to serving their consumer base.

Precision is very important when creating strong and durable products. To make sure that each and every piece is produced to the right measurements, Moldie uses special die casting techniques. Broadly speaking, this means every product will bore the same level of similarity to the next one in terms of form and function, and everything will fit seamlessly when used with other products. In addition, the process of die casting enables highly precise details for more intricate designs, allowing for beautiful shapes and textures to be made on the surface of every design. Such precision is important in helping to ensure high-quality production.

Die casting technology is efficient and is one of the biggest USP when it comes to productivity. With this technique, Moldie is able to generate a ton of unique pieces at once. This magnesium alloy casting allows them to create far more products in a lot less time than through other means. This speed is particularly important for large-scale projects, where a lot of parts need to be produced quickly. With the help of the die casting technology, Moldie can achieve the highest level of efficiency and productivity, allowing them to offer premium quality products at a fast pace and satisfy their customers’ needs in a timely manner.

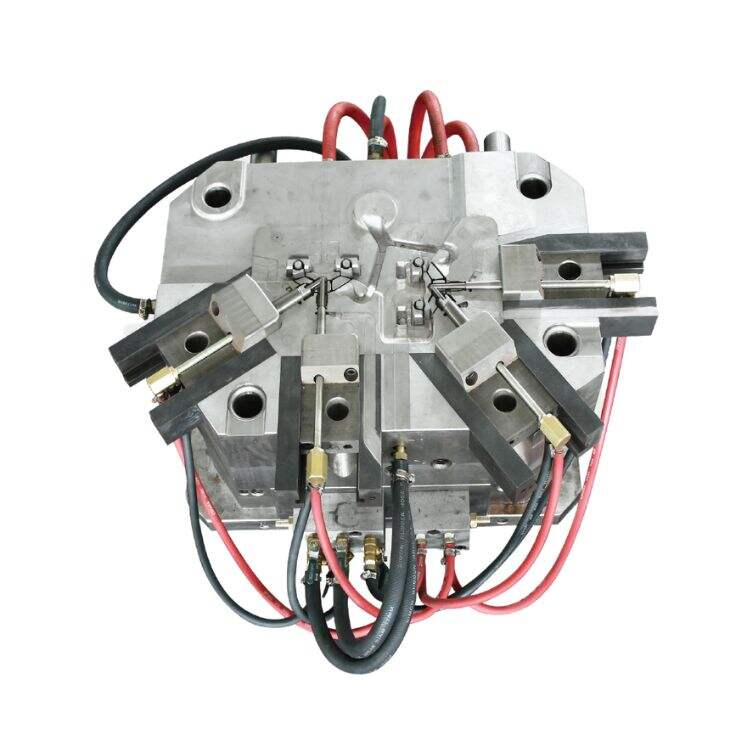

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.