Moldie manufactures areas of expertise machines known as Injection Moulders. These machines are so cool because they act like little workers building products in a cost-effective, precise manner. Injection moulding involves melting the materials using heat and then injecting them into a mould. As the molten materials cool down, they assume the shape of the mould, and solidify to become a product. Then we can do that with lots and lots of different things to make all kinds of different stuff we see every day, things like toys, parts for machines, and even things that are used in important medical tools!

Injection Moulders are great because they are capable of producing parts much faster. This is a tremendous asset for companies that requires a lot of products to be made quickly. By controlling the heat, speed, and pressure of the machine, each item can be made carefully and in less time. It would be like having a really fast cook who always cooked your favorite meal perfectly! It is equally important to design the mould well which uses less material. This reduces the cost of producing products, benefiting both businesses and their consumers. And when it uses less material, it’s better for our planet because less waste is being created.

As technology improves, so does Moldie, proud to offer the latest Injection Moulders. And now, energy saving and more effective electric and hybrid machines. They make business more cost effective and eco-friendly through new concepts and designs, equipment that do their tasks better. We are also introduced to new materials such as bio-plastics and composite materials which offer greater variety when it comes to designing products. Bio-plastics are derived from natural materials, giving them a more eco-friendly profile. So, when we design our products, we can keep our world clean and healthy in mind.

Choosing the right Injection Moulder for a project is quite essential. Every machine has different specifications that may affect its quality as well as cost. For example, some machines are suited to making small items, while others allow for larger pieces. The way the mould is designed and the materials used matter too. Because not every injection moulder is right for every job, it is important to choose carefully. Moldie has a few kinds of machines that will fit unique project requirements. That way, businesses can choose the machine that is ideal for their desired production process.

Injection Moulders are fantastic machines, but can sometimes experienceissues. Common problems include low product quality, incomplete filling of the mould and surface defects. These issues can be annoying, but the right help can often solve them. To a large extent, poor product quality is the result of poorly designed mould. The drawback with this is if the mould is not properly made, it can create problems with the final product. This can be resolved by modifying the mould, or adopting a better batch material that is compatible with the machine. Moldie's injection Moulders specialists can assist to identify and repair any issues with Injection Moulders. They are knowledgeable and experienced enough to diagnose the issue and recommend the right solutions.

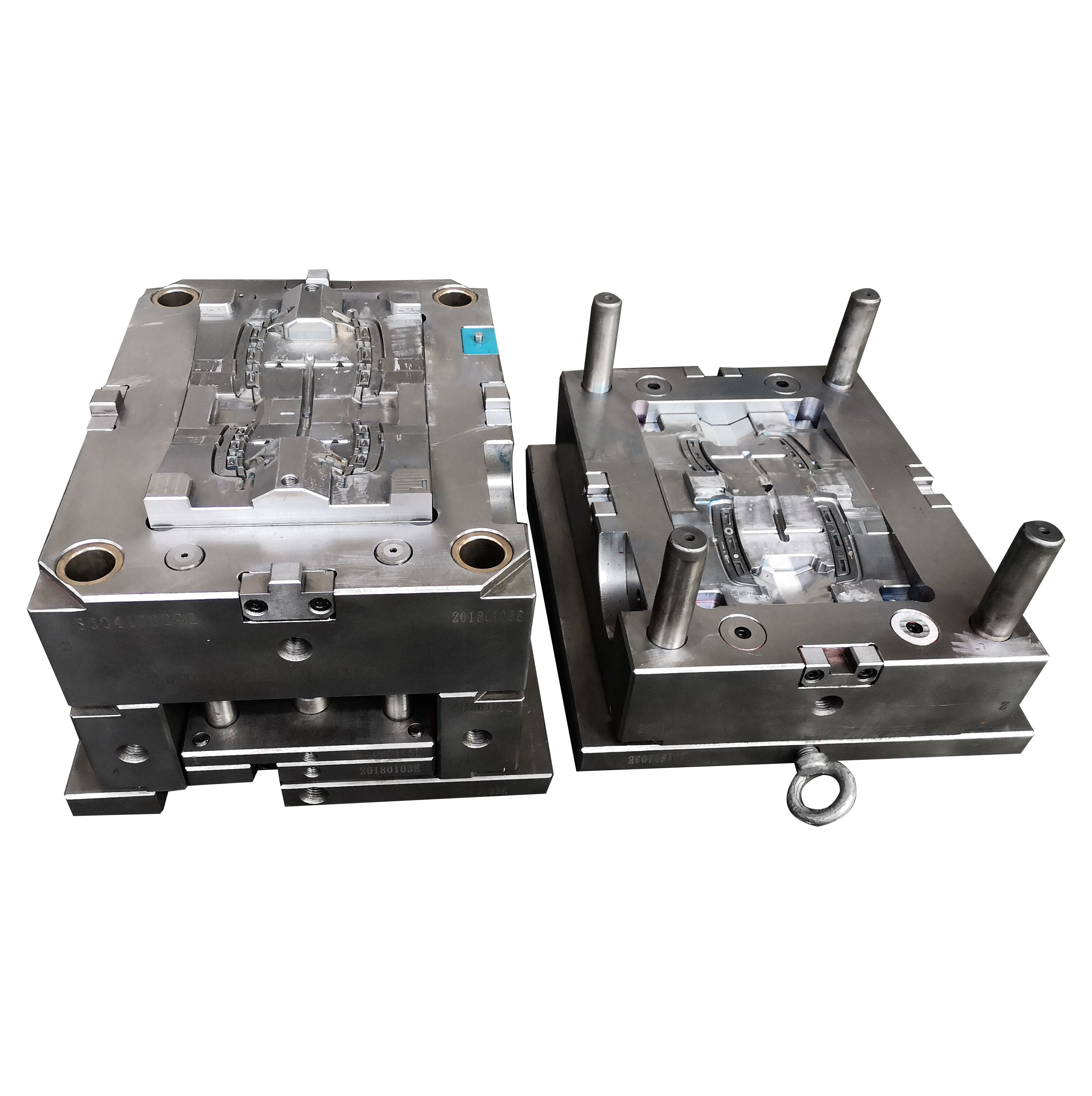

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.