Hello, friends! We come to you today to share some great news about "HDPE Injection. Have you heard this term before? If not, that’s totally fine! So we are here to make an easy and simple words explanation of it for you to better understand it.

Introduction to HDPE Injection:HDPE Injection is a unique process in which various products are created from the plastic material called High-Density Polyethylene (or HDPE). This is very strong material which means it can hold up for a long time without breaking. It is also resistant to things like chemicals that can damage other materials, and it does not get moldy. Due to this remarkable feature, several daily routine objects around you are manufactured using HDPE Injection. Plastic containers used for food, colorful toys for kids, and even water bottles we drink from are just some examples.

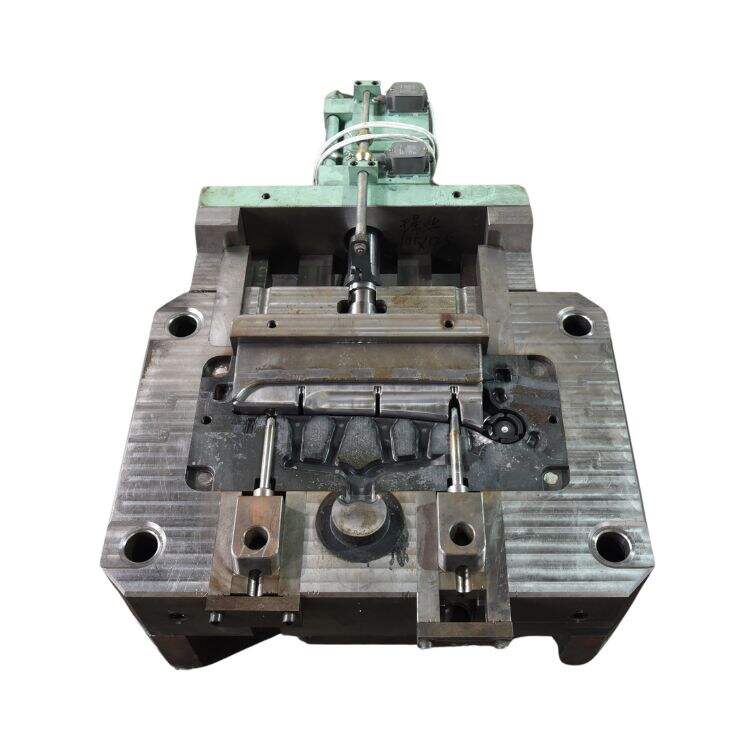

So, what is the actual process of HDPE Injection? It all begins by heating up the HDPE or high-density polyethylene (plastic) so that it gets extremely hot and turns into a liquid form. Once melted, the liquid HDPE is forced into a special cavity that shapes it into the specific item we need. It is in the mold, it cools out again and becomes solid. There are many benefits to this style of making. For starters, it’s capable of turning out a vast quantity of products in a short time, which means even a small factory can churn out a lot of products in a matter of days or weeks. It also keeps the products uniform and of the same quality. HDPE Injection can create products with complex shapes and designs, which is an advantage for manufacturers.

And one of the most amazing parts about HDPE Injection is that it is environmentally friendly. HDPE is a recyclable material. This means that when we are finished with an HDPE product, it can be melted down and reused in new products rather than simply disposed of. This contributes to waste reduction, which is a major issue for our planet. HDPE is also great because it will degrade fast — even in nature. This means that if it does go outside, it won’t stay around for long, which is better for the environment. Because of all of these reasons, HDPE Injection Responsible for Good Jobs for Products

If you need to make a large quantity of products, you should be looking at HDPE Injection! This is a fast, effective, and trustworthy process that enables factories to create a vast number of products in a few hours. Its ease of use is a huge time-saver and cost-saver as a result. This matters to companies, because it allows them to spend less on manufacturing products but churn out big volumes. Furthermore, HDPE Injection allows the company to replicate their products many times over with all of the same high caliber, ensuring customer satisfaction.

One other advantage of HDPE Injection is that it allows for the production of complex-shaped products. Manufacturers can create unique and more complex-patterned items that may not be as manageable to produce with other production processes. With the aid of HDPE Injection, these unique products can easily be created, making sure that all products created are top-notch. This is fantastic in terms of production brands and the people who buy them.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.