Have you ever wondered how some of the toys and products you use every day are made? A lot of this plastic stuff is made through something called injection molding. This dissolution process enables manufacturers to produce large quantities of the same item in little time. For instance, it may be utilized to manufacture toy cars or maybe even some crucial components of actual vehicles that drive on roads. We at Moldie are professionals in injection molding, and we do great work, producing quality plastic products with care.

Each industry has its unique plastic product needs. At Moldie, we provide bespoke injection molding solutions for numerous fields, and this is exactly why. We partner with different kind of businesses, automobile industries, hospitals, and others to ensure that we are creating the exact product that is suited for their exact needs. Our experts take the time to learn what each industry needs, in order to build products that meet those specific needs. If we can do that, it means that we are doing the right thing with every product we build, and also that it meets the expectations of our customers.

Efficiency and cost saving are two very main objectives each time it is about manufacturing. We employ state of the art injection molding techniques here at Moldie that allow us to work quick and keep our customer costs low. We can produce highly detailed and sophisticated plastic parts comperatively quickly relative to our top of the line machines and processes. This reduces lot of wastage, which indicates that we use lesser resources and save cash along the way. We can deliver our quality products to customers at prices that make sense for them by optimizing everything.

We know that to make great plastic products you need the latest technologies, and at Moldie that is exactly what we do. That's why we constantly invest in new tools and machines to enhance our manufacturing processes. We use advanced computer-aided designs (CAD) which help us map our products even before they go into actual production. We also leverage robotics technology for production. These techniques ensure that we are able to manufacture plastic products that not only meet the highest industry standards but also surpass them in many cases! Innovation: Our commitment is to keep ahead of the technology curve, so we can bring top-class products to our customers.

By working closely with our clients, we are able to deliver mold solutions that not only meet their requirements but take their needs into consideration as well. At that time, we realised that the only way to deliver successful injection molding solutions, is teamwork. From initial design to production, our experts are here to help you every step of the way. This is to ensure that your plastic products of the highest quality attainable and that they fulfil your individual utilities. Working alongside you allows us to deliver final products that meet your exact needs and also work well in your niche.

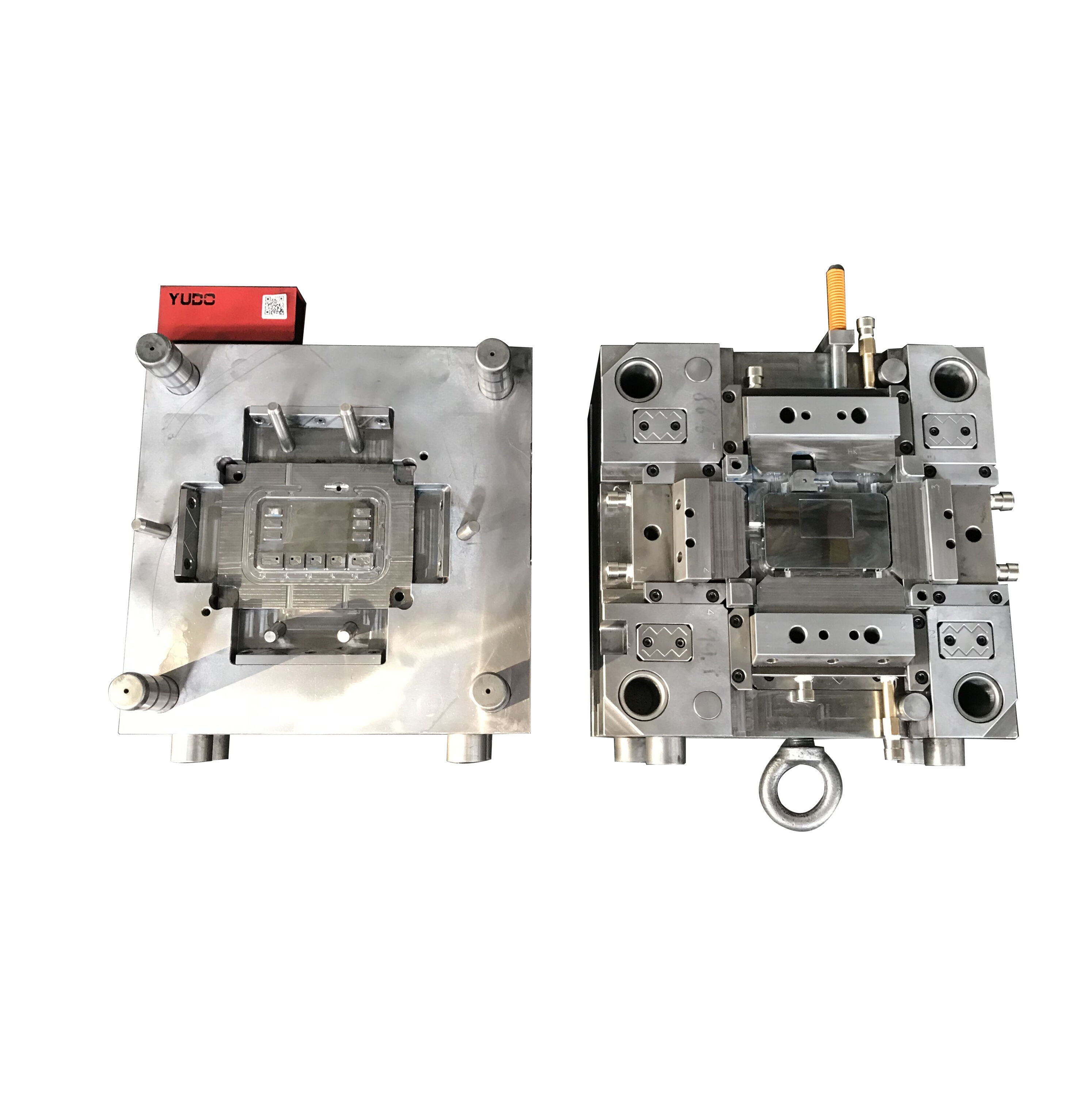

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.