That's how parts from Moldie will appear and on with what you get! This means there are no errors in their manufacture. Moldie employees have very good skills on their jobs. They have an eye for the finer details. These meticulous efforts ensure perfection in every element while upholding high standards. Due to their efforts, consumers can rest assured that they are receiving the highest quality of moldie aluminum die casting.

Moldie has smart machines that ensure the product quality is high-grade. These machines are specialized only for die casting metal components. They do an excellent job of work and can produce parts that fit together like a glove, which is critical. If they fit well together, they'll work better in whatever the project they are needed in. Which tells you that not only the products from Moldie are solid, but as well durable and trustworthy in a long run.

Moldie’s machines can produce part features in minuscule dimensions, known as tolerances. This matters to make sure all these works nicely together. When all the pieces fit together nicely, the entire whole product is stronger and more reliable. Customers can rest assured that they are buying a quality moldie aluminum die casting molds that will serve long.

The metal Moldie uses is well-known for its strength. They melt and then rapid cool the metal in the process of die casting. This rapid cooling hardens and toughens the metal, making it challenging to break. Moldie also designs their parts to be very strong. They know their products are used in challenging environments, so everything is engineered for ruggedness.

Moldie also has extra-ultra-accelerated machines that produce high-volume parts. This is awesome because when you order from Moldie you get your parts quick! That’s helpful for those who find they need (or break) parts for their projects quickly, as you don’t have to wait long for your order. They can do this because they produce things efficiently and can provide customers with what they need without waiting.

Moldie can create custom parts for any project. The awesome part is that they can make parts in various shapes and sizes based on your requirements. If you need a specific metal part for your project, Moldie can make sure you have exactly what you need. They realize that no two project plans look the same and they will work hand in hand with you until you have what you need.

This implies that, if you have an amazing idea or a need that is not met, they are open to hearing it and working with you to see your vision through. They need to ensure their clients are satisfied with what they get. Moldie desires to ensure their customers know they are there for them, offering customized moldie aluminum die casting mould rather than a one-size-fits-all model, and including them in every step of the process.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

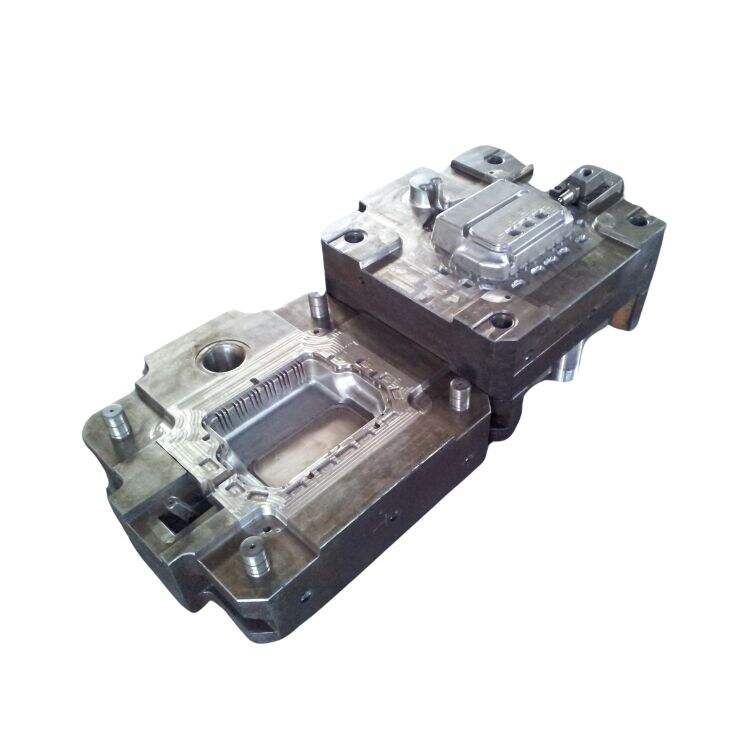

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.