Are you interested in how the toys you play with or the cups you drink out of are made? Injection mold makers are a big part of making these products become a reality! These are the people who make special tools, called molds, that shape plastic into all kinds of products. To explore what they do and why their work is so crucial!

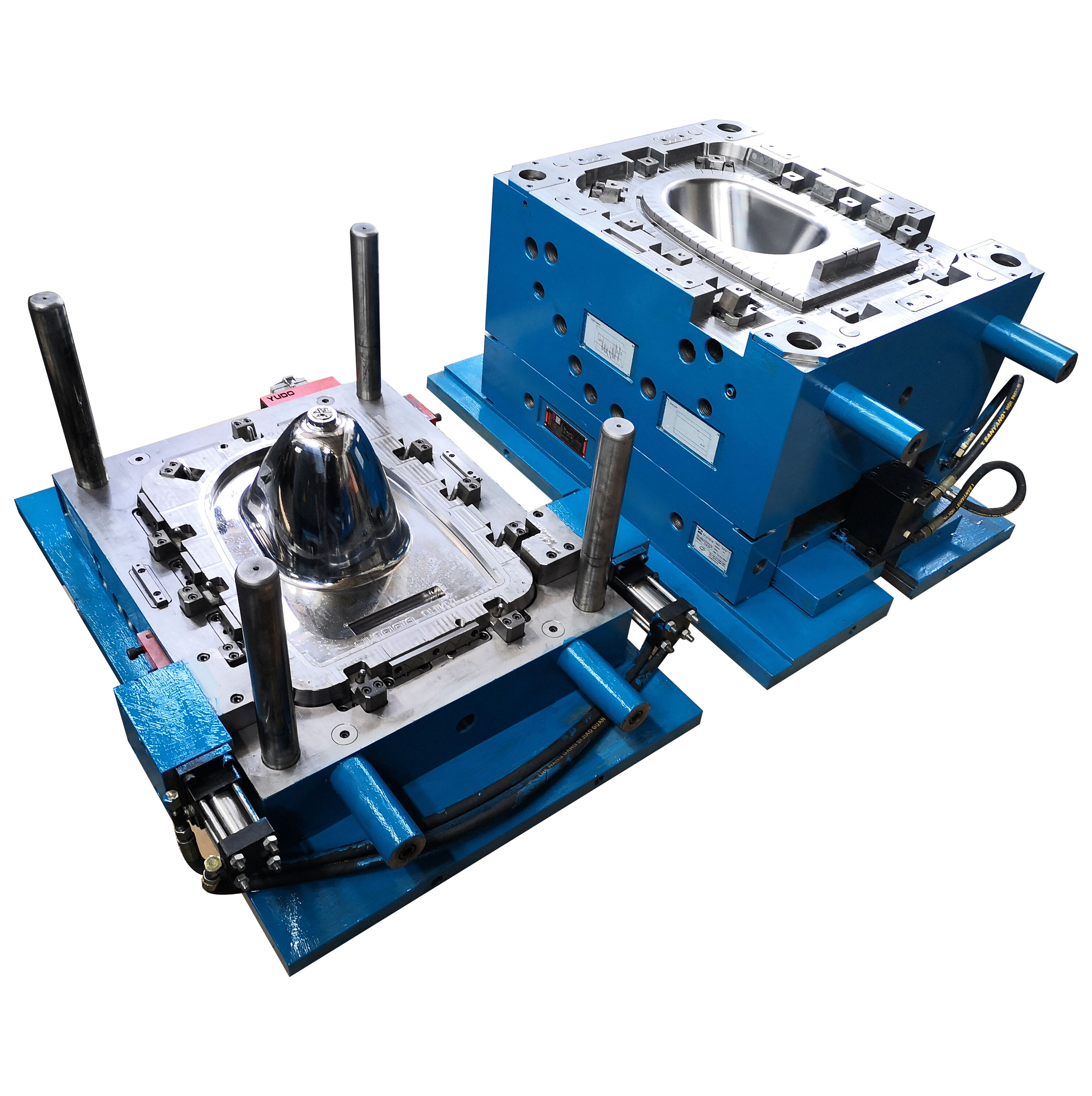

Injection mold making is a method for creating a special tool that allows a lot of plastic products to be formed simultaneously. The tool is called an injection mold and is usually made from strong metals such as steel or aluminum. The mold is specifically designed to a shape and dimension of the product you wish to have. If the mold is for a toy then it will be in the form of that toy. Injection mold makers use heavy machinery to carve the metal into the proper shape for the mold. They need to learn to run these machines properly so that everything runs smooth.

Injection mold makers are specialized workers who make molds to create a wide variety of plastic products. They get really creative with their choice of tools and techniques to create their molds. In turn, when they begin working on a new mold, they are working off of detailed plans and blueprints that guide them precisely what to complete. This helps them design molds according to the exact requirements of their client. Mold makers need to be extremely precise because even the smallest error could cause the mold to fail. If the mold is not done right, then the end product may have issues as well. In order to speed up the process and improve it, mold makers usually work in teams with whom to complement and share ideas.

Injection mold maker are the backbone of plastic product making. After a product has been designed and the specifications have been worked out, the mold maker comes in and makes the mold that will be used to create it. They work with injection molding machines that squirt hot liquid plastic into the molds to make things we use every day. Those products include toys and clothes hangers, car parts, and even medical devices! Many of the plastic products we depend on in everyday life would not be possible without the help of plastic injection molding.

From simple to highly complex designs, injection mold makers produce molds in all types and shapes. Certain molds require complex forms and angles, which can prove challenging to obtain. Building these more elaborate molds requires a fair amount of skill, patience and precision. Add to that the huge drive for mold makers to think outside of the box and create new, breakthrough molds to accommodate ever-changing demands in the manufacturing sector. They might have to be creative and develop ways to solve problems they encounter in their mold-making journey.

Some of these innovations have been implemented by injection mold manufacturers, as technology continues to evolve and new materials become accessible. They must remain updated about new software, machines, and techniques that will enable them to complete their jobs better. This could involve training classes or workshops where they can gain new abilities. They must also be aware of trends in the industry to continue producing quality molds that fill the needs of their clients. Furthermore, there are not only industry-wide but economic and environmental pressures that are driving the push for more sustainable products, so mold builders will need to adapt their processes to minimize waste and develop more eco-friendly solutions as well.

Moldie focuses on injection mold making. They have a team of professionals who are very good at making the molds of plastic product. Sourcing from the best manufacturers allows Moldie to ensure the design meets the highest standards! We make sure that the molds we produce are not just cost-effective but also sustainable. They are committed to minimizing waste and utilizing sustainable materials whenever feasible. * Moldie always keeps pace with new developments in the manufacturing field to deliver molds that respond to the changing needs of their clients.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.