When you think of toys you likely are not thinking about how they get made. A lot of toys are made using a process known as: injection molding. So, what exactly is injection molding? Well, it’s when hot plastic is forced into a mold to create a shape, such as a kiddie car or a doll. This is a very interesting process because it requires many timepiece to be synchronized, and balanced to actually make the end toy work. These parts are referred to as injection molding. They play very important roles to ensure that the toys are well manufactured and appear perfect.

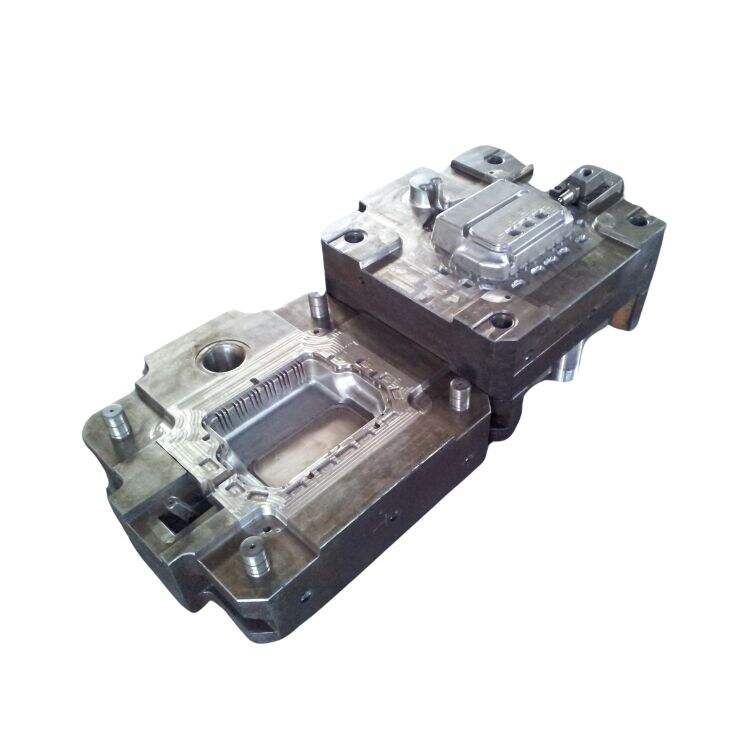

And now, we will discuss some of injection molding’s most important components. Injection mold tooling is made up of several different parts, each of which serves an important function. The mold consists of two halves — one half remains stationary, while the other can move. Once the mold closes tight, it forms a cavity that gets filled up with the melted plastic. Once the plastic cools down, the mold opens again, and the final toy pops out. And this is how they mold toys in very precise way.

However, besides the mold and sprue bushing, the other elements will be ejector pins and sliders (among others). These pieces also aid in expelling the completed toy from the mold once it is complete. The cooled channels are also a vital part of this process.【43†source】 This allows the plastic to cool evenly and less expensive. It matters a lot because if it doesn't cool correctly, it causes defects and issues with the final toy.

Now, let's take a give a closer look on what it take to make a successful injection molding. There is an important section that needs to be utilized. Make sure that you have a good, strong mold that is made of quality materials. It’s important that the mold is created with extremely accurate measurements. That way the final toy will be true to life and as it should look. It should also be capable of enduring the extreme heat and pressure, which are vital for the injection molding process.

Time-tested, all of the dimensions of plastic injection molding must be precise. All of its components must be manufactured to high tolerances, and fit together precisely. The mould works effectively when every bit, it fits correctly. But if any component is even slightly out of whack, it can result in defects or inconsistencies that compromise the final product. This means that the toys could potentially not match to how they should look or work that way and this is not what we want at all from our fun and rolling!

Hence, in order to produce the best toy there is, it is imperative to have the correct components in your injection mold. Utilizing quality components especially made for the type of plastic you're dealing with will really set you up for success with the way that the final toy comes out. To illustrate, a really good cooling system can ensure that the toy doesn't warp or bend out of shape. It will also enhance the appearance of the toy when completed.

Choosing Injection Mold Components: Why You Need A Trusted Manufacturer When it comes to choosing injection mold components, your best bet is to work with a reputable manufacturer who can tailor the components to suit your exact project goals. We produce high-quality, strong, precise, and customized injection mold components at Moldie. The feedback we have on our work defines us, and we are willing to partner with you to succeed in your projects.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.