About Injection compression molding is a unique category of injection molded plastic components that we find in a wide variety of products It all begins with plastic being shaped in a process known as molding. A mold is a type of hollow container that shapes the plastic into its desired final form. Once the plastic is poured into the mold, The mold is pressed together. It is by this pressing action that we help the plastic take the shape that we desire. In fact, lots of industries — from the automotive industry that manufactures cars, to the medical field that produces equipment, to toy manufacturers — use this process to make their products. The reason this technique became so popular through the years is that it enables manufacturers to produce high-quality plastic components in a fast and efficient manner.

Injection compression molding works in two steps. The plastic is then pressed together tightly to the rockform, giving it the right shape once released. This step is crucial, to remove air entrapment within the plastic. If not removed, these air bubbles can leave weak points in the final product. Pressing the mold also fills every nook and cranny of it with plastic. Distributing the plastic evenly leads to a better, and higher-quality finished product.

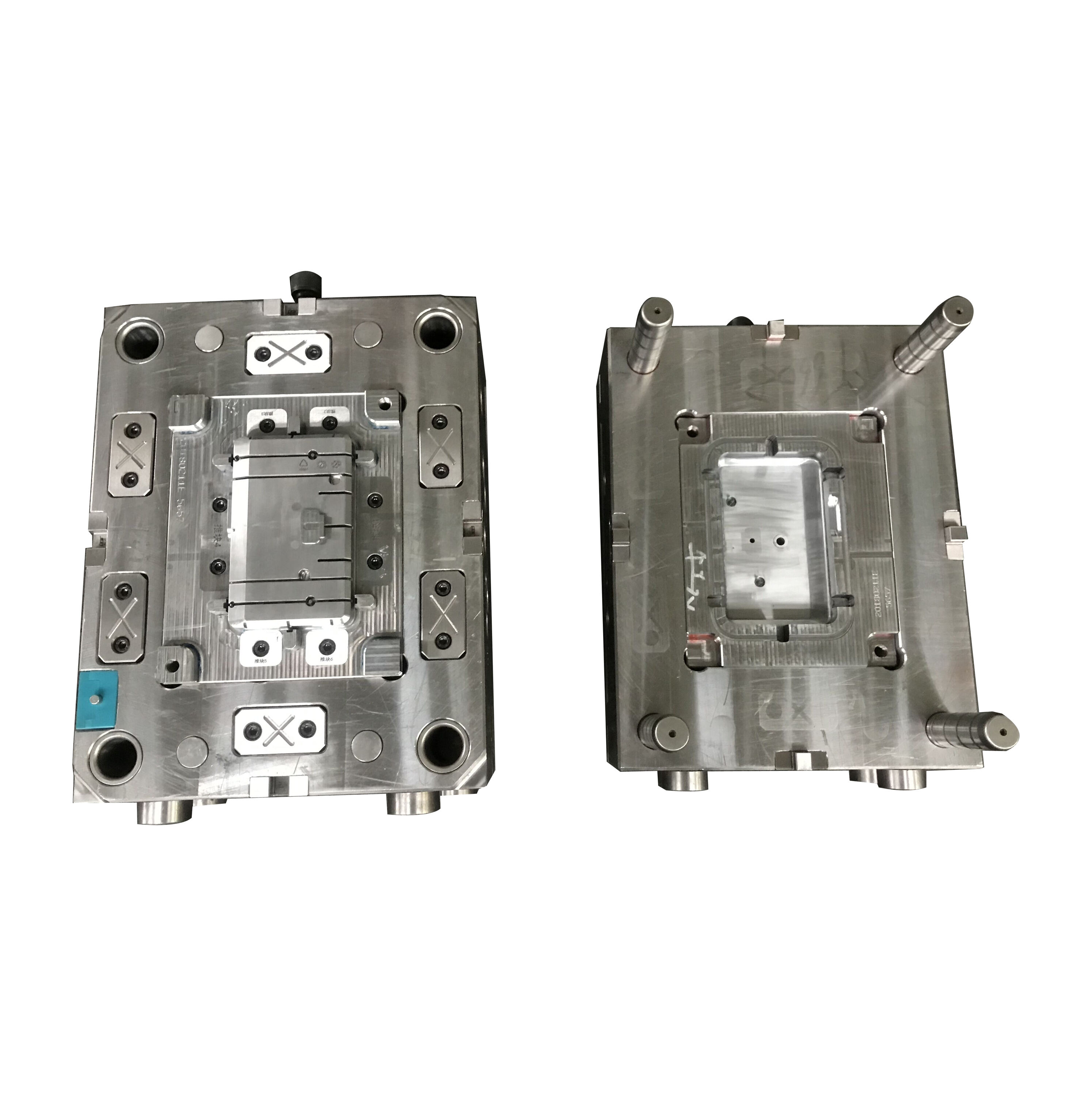

The mold itself is integral to this process. For it to function properly, it must be created properly. The mold is designed for the plastic to be injected and pressed against it. Not being made strong enough could cause it to break or warp during the process. Moreover, quality of the materials used to make the mold is also essential. It also makes sure that the forces exerted during the injection and compression process can be applied to the mold without damaging the mold.

Selection of the correct type of plastic is another important component of plastic injection moulding service. The plastic you’ll apply needs to flow freely into the mold. For example, if the plastic is too thick or doesn’t flow well, it won’t fill the mold. This can result in incorrectly shaped areas of a part. Also, the plastic should not shrink too much when it cools down. Overshrinkage of the plastic in this way can lead to an incorrect final product size or shape, leading to difficulties in use of the product.

After you have chosen the mold and the kind of plastic, the next step is to prepare the equipment responsible for extrusion and compression. This requires making changes to the machine’s settings to ensure that the plastic is injected into the mold at the correct speed and pressure. These settings need to be carefully monitored. This can cause inconsistencies in the parts being produced. So by making sure, you are doing everything the correct way, you end up with a consistently reliable process that will create good parts every time.

One more benefit of the process is that the pressing enhances the surface finish of the plastic component. The plastic is distributed evenly across the mold, resulting in a flat and smooth surface. This is relevant for the look, and also for the performance of the product. Having a smooth surface can allow parts to fit better and operate more efficiently.

Finally, it is important that high-quality materials be used for the mold, plastic, and machine. High-grade materials are more726 durable and are better able to deal with the pressure and considerable wear which occurs in the injection compression molding07405 process. Investing in good materials leads to better product quality and longevity for your equipment.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.