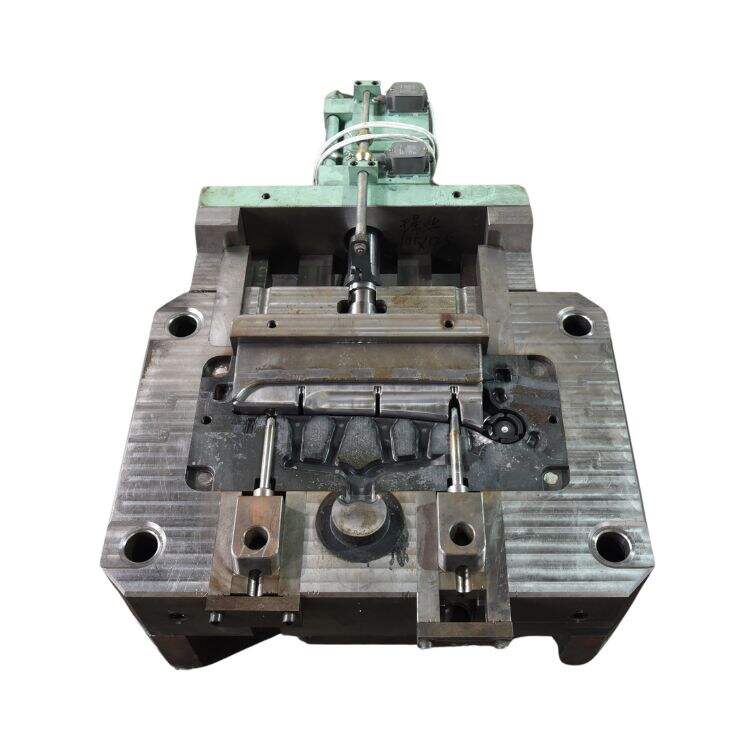

Many factories use a casting die design process, which is a critical stage of creating parts. The entire process starts with creating a mold, a specific shape that you can use to make multiple copies of a part. The mold, or die, itself, is typically made of hardened steel. It has two pieces that snap perfectly into each other to give us the shape of the part we want to create. This enables manufacturers to rapidly and efficiently produce large quantities of identical Die casting parts.

There are many considerations to be made when creating a casting die, and planning is absolutely key. However, the first thing you have to think about is the material you will use to create the part. Every Die casting die material has its uniqueness. This means that when they melt and are poured into the mold, they behave differently. For example, we might melt some materials at higher temperatures or cool them down quickly. Understanding these quantities aids in selection of the material for the job.

The other major consideration is the part geometry. The shape and design of the casting die should be tailored to the specific shape and size of the part, including any features or details that should be incorporated. If the die is not well-designed, it could result in problems in the final output; for example, defects or even breakage.

More complex the casting die, longer the time taken to produce a product. So a properly designed die for casting can turn out parts really quickly, and eliminate waste. Computer-aided design (CAD) software could help to improve the design. These programs assist engineers in designing and adjusting the mold via a computer. This means that they can easily review their designs and modify the mold before any production actually occurs.

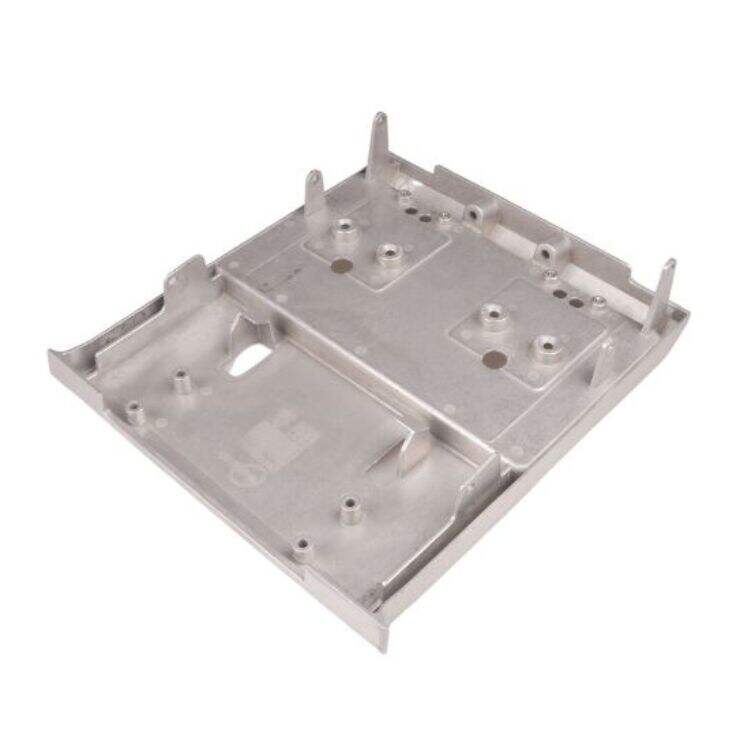

Today, designing casting dies is very challenging, especially regarding the production of complex parts. The Aluminum die casting parts often have unique shapes and must interlock very tightly. At the same time, initial solutions to some of these difficult problems have been enabled through new materials and new technology.

For instance, newer materials such as ceramics and composites are increasingly employed. These kinds of materials are stronger and could better withstand heat than traditional options. This means they can make the casting die more robust, with longer operational lifetimes and improved efficiency. Furthermore, there are growing use of 3D printing in casting die design. This lets engineers rapidly design and test new designs for the molds. It accelerates the cycle of prototyping and iteration, which is a huge benefit, as it enables you to test concepts faster and identify workable solutions sooner.

Creating casting dies by Moldie is already a complex task, and it is even more complicated when creating high-precision parts. These parts have more complex shapes than standard parts and require even tighter tolerances — they need to fit a lot closer.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.