Moldie is a unique company that specializes in a part manufacturing process called precision casting. As critical as precision casting, where hot liquid metal is poured into metal molds. They are specially designed molds for the different metal parts we need to shape them for serval different use. Using this approach means that Moldie can produce metal parts with a high degree of precision and in a short amount of time, which is critical in many sectors of industry mold injector

At Moldie, we are constantly exploring ways to enhance our operations. Innovation is the name of the game for continued success in the industry. We have a group who cares a lot and are always up with alternatives to optimize our castings. It means we are constantly trying to think of near ways of doing things so that we can remain leader ahead of other companies.

Moldie have been introduced among best die casting companies. We are recognized for our dedication to quality in manufacturing and innovation. We are proud of our accuracy, speed and quality of goods. We want to be sure we provide the best service and product to our customers and that they are completely satisfied with what we bring to the table.

Our track record is long and successful, with many clients relying on us for their metal part needs at fair prices. And that's why we have become the preferred choice for many companies that require high-quality parts in metal. A reputation for excellence helps to build and preserve solid relationships with our clients, they know they can count on us.

We are making a concerted effort to incorporate green practices and use innovative technology because we want to lead by example with other companies. We are able to offer high-quality products without sacrificing our environment in the process, which is an important injection molding tooling commitment to sustainability.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

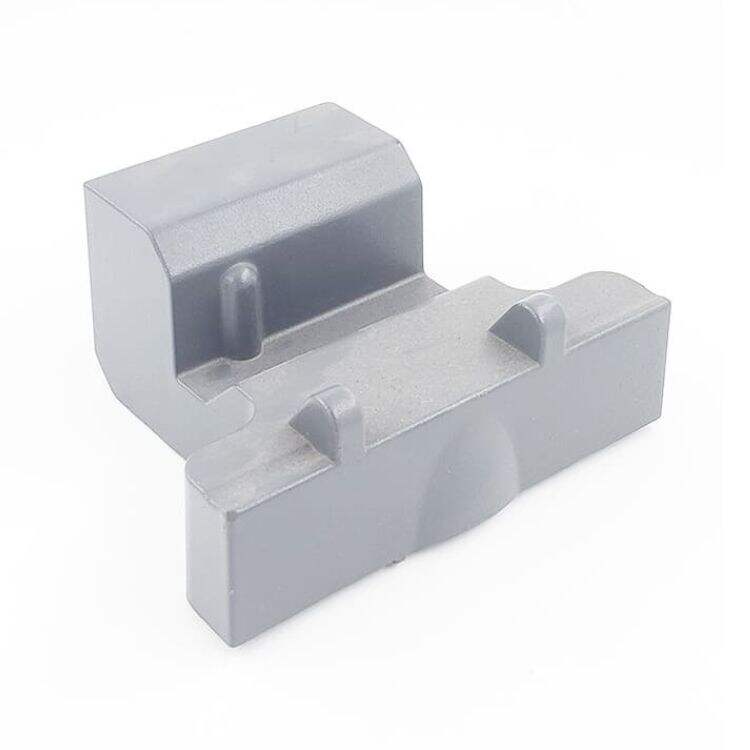

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.