Hi there. We will talk about mould tooling clearance in plastic mold manufacturing today. Tooling tolerances might sound a bit fancy, but it's not that difficult to understand. Let us find out why with our buddy, Moldie.

What are Tooling Tolerances?

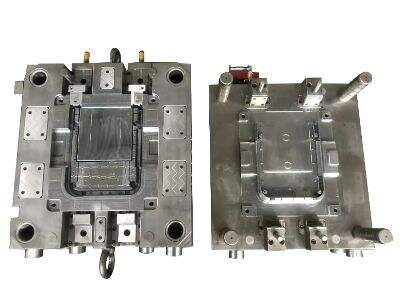

Tooling tolerances are the small variations in the size of a plastic mould. Think, for instance, of making sure all the pieces of a puzzle fit together just right. When tooling tolerances are made to be very tight and accurate, the idea is to hold the same size and shape product each and every run. This ensures that every product made from the mould looks exactly the same, without errors or variations.

Producing Quality Products with Highly Accurate Tooling Tolerance

Manufacturers can ensure that their products are of a very high quality, says Moldie: “When tooling tolerances are tight, manufacturers can produce very high-quality products.” For company like Moldie it’s really critical to give the best product to customers. With the precise tooling tolerances, every product sure meet Moldie high requirements, making the customers satisfied and fidelity.

How Do Tooling Tolerances Impacted?

With plastic products, performance and longevity are paramount. If tooling tolerances are not tight, products may not fit together correctly or may feel flimsy. However with tight tooling tolerances, products not only look the same, but they work well and last a long time too. This is important so that Moldie’s customers will be able to have faith in the company’s products into the future.

More of the same in Plastic Mould Manufacturing

Precision consistency is vital when it comes to producing plastic molding. With tight tooling tolerances, manufacturers can ensure that every product they make is equally good. This means every piece that comes out of the mould is identical to the next, with no defects. Consistency & Accuracy In Moldie’s world, product inferiority isn’t an option, and it is possible thanks to the high attention that they give to their tooling tolerances in order to serve a great product to their customers.

How Tooling Tolerances Will Save Time and Money

In a production setting, efficiency is key, and waste is costly. Good tooling tolerances contribute to make this possible. When products are precision made, there’s less room for error, so less material and less time is wasted. This is made possible by the work of Moldie, Vasudevan and Guth, which allows Moldie to perform better and faster. Moldie can slam out sexy high-end products in a smart way by focusing on good tooling tolerances.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

HU

HU

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

IS

IS

HY

HY

AZ

AZ

KA

KA

BS

BS

LA

LA

KY

KY