Take a moment to look around you; have you noticed how many things are made of plastic? It’s amazing! Plastic is everywhere from the toys we play with to the commonly used items at home. But have you ever thought about how they create these kinds of plastic products? And this is where something known as plastic moulding comes in, and it’s a major contributor to actually creating all of these things.

Moulding products made of plastic can be manufactured into a variety of shapes and sizes. This lets them be really good at producing all kinds of things. While it may be difficult to shape materials such as metal or wood, there are many ways of moulding plastics. This versatility allows designers and manufacturers to have products that serve a wide array of needs and purposes, thus making plastic a very versatile material.

Plastic moulding products are fast to manufacture which are also one of the coolest things which helps you save money. These products can be very fast produced in large amounts also which helps reduce costs for companies. So when things are produced rapidly and in volume it minimizes production time and cost. And plastic is lightweight, which makes it convenient to carry and pack. Because they are so light, it also saves coin on the expense of shipping as lighter items take less to transport.

Plastic moulding reap into the opportunities of taking a turn on unfamiliar shapes and make it into innovative concepts. Because plastic can be molded into so many different shapes, designers have a lot of creative freedom and room to experiment. For instance, they can design toys in interesting shapes to engage kids. Thanks to this creativity we already have invented so much useful, nice and interesting products. Functional and aesthetically pleasing items are great for counter place.

After all, lots of individuals worry about plastic’s impact on our environment. This is a big topic one and Super Super]]Please follow the verification link to verify your new account. The good news is that we can do plastic moulding in a more planet-friendly way. We can even make new products from recycled plastic. This helps reduce waste as it slows down the amount of plastic that gets thrown away. Another sustainable benefit is through the use of recycled materials, we help to conserve natural resources, as we are utilizing the materials that we have already used. Moreover, plastic is commonly more durable than other materials. This means they don’t need to be replaced so frequently, which is good for our wallets as well as the environment.

Plastic moulding products are used across various regions and industries. For example, they are often used to produce auto components automotive sector. It's also crucial because cars require a large variety of parts, and plastic moulding enables these parts to be manufactured very quickly. In hospitals, they are used to create medical devices and equipment that is important for health care. Besides, mold plastic injection are used extensively in the packaging sector for the manufacture of various food containers, bottles and packaging materials. This helps ensure that our food remains safe and fresh.

Moldie punchers moulding factory is specialized in producing plastic injection mould products for various fields. We use cutting-edge plastic moulding techniques to design new, innovative products that fill a gap in the market for our customers. We care also a lot about the environment. So we use recycled plastic whenever we can to reduce waste and use more sustainable materials.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

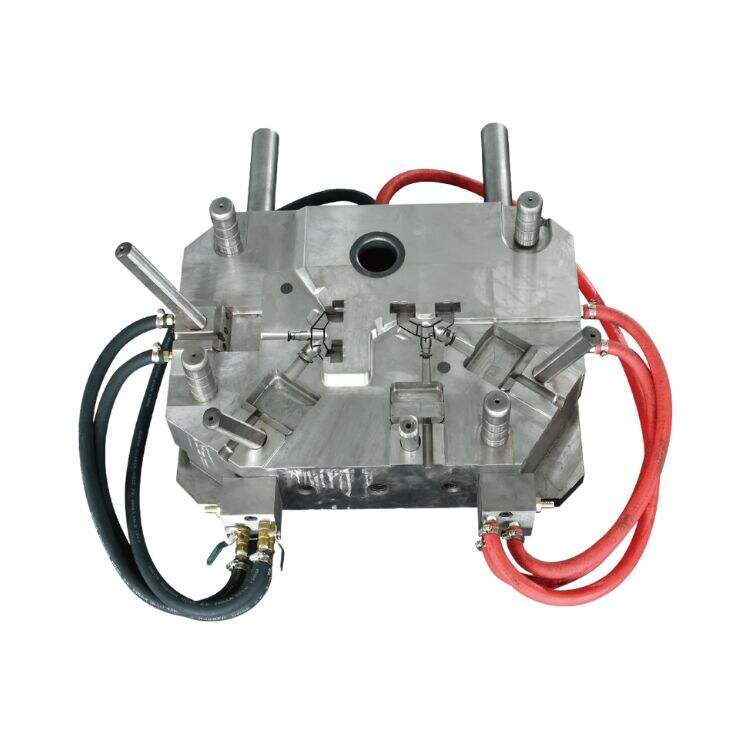

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.