Have you ever wondered how toys and water bottles or car parts get made? Everything starts with the magical process known as mold plastic injection. This jargon simply means melted plastic is injected into a device called a shape or mould to change it into something useful and new. There are tons of things we use on a daily basis that are made this way!

Injection moulding is a process of plastic forming that is been around for more than a century and still an extremely vital process in the reproduction of many products;Plastic injection mould is a process that has been around for over 100 years and still plays a major role in manufacturing many products today. During this process, tiny bits of plastic known as pellets are heated until they melt into a thick soup. Once melted, the plastic is forced into a mould (a hollow shape), which gives the plastic its shape. After the melted plastic has cooled and solidified, the mould will be opened so the new part can be removed. Using this method can make really fine details — the tiny features on a toy, for example — that would be difficult to produce in other ways.

It revolutionised the way many things are manufactured in factories, plastic injection moulding service. Before this process was designed, items were really approached from a steel or wood perspective. The process was slow and could get quite costly to make items from these materials. However, using plastic injection moulding, things can be made relatively quickly, and cheaply. That means many goods are easier to find and cheaper to buy for everyone. For instance, used your mind for a little on how many toys you can purchase in a business. Well, it can be manufactured sooner due to plastic injection moulding, and can be marketed at pocket-friendly pricing!

Plastic injection moulding is extremely versatile and useful when producing a range of different products. That makes it ideal for designing new products. This makes it possible to create weird and wonderful shapes and sizes, so beautiful and functional products can be made. For instance, a water bottle can be perfectly designed to sit in the palm of your hand with a fun look. Additionally, plastic injection moulding has numerous advantages over alternative manufacturing methods. One major benefit is that it can build parts that are sturdy yet light — exactly what is needed in many applications. This matters, as it contributes to creating products that can easily be carried and used on a daily basis.

Plastic injection moulding, is a process that has some critical stages. It starts with tiny plastic particles known as pellets, which empty into a large vessel called a hopper. This hopper sends the pellets into a heated tube, where they liquefy. The plastic is pushed then through a mould that is closed tight. When the plastic is completely melted it becomes a thick liquid. The mould remains shut until the plastic cools and solidifies. When the plastic sets and cools, the mould opens, and the new part is removed. That’s why many different products can be made in a short period of time—this whole process occurs very rapidly!

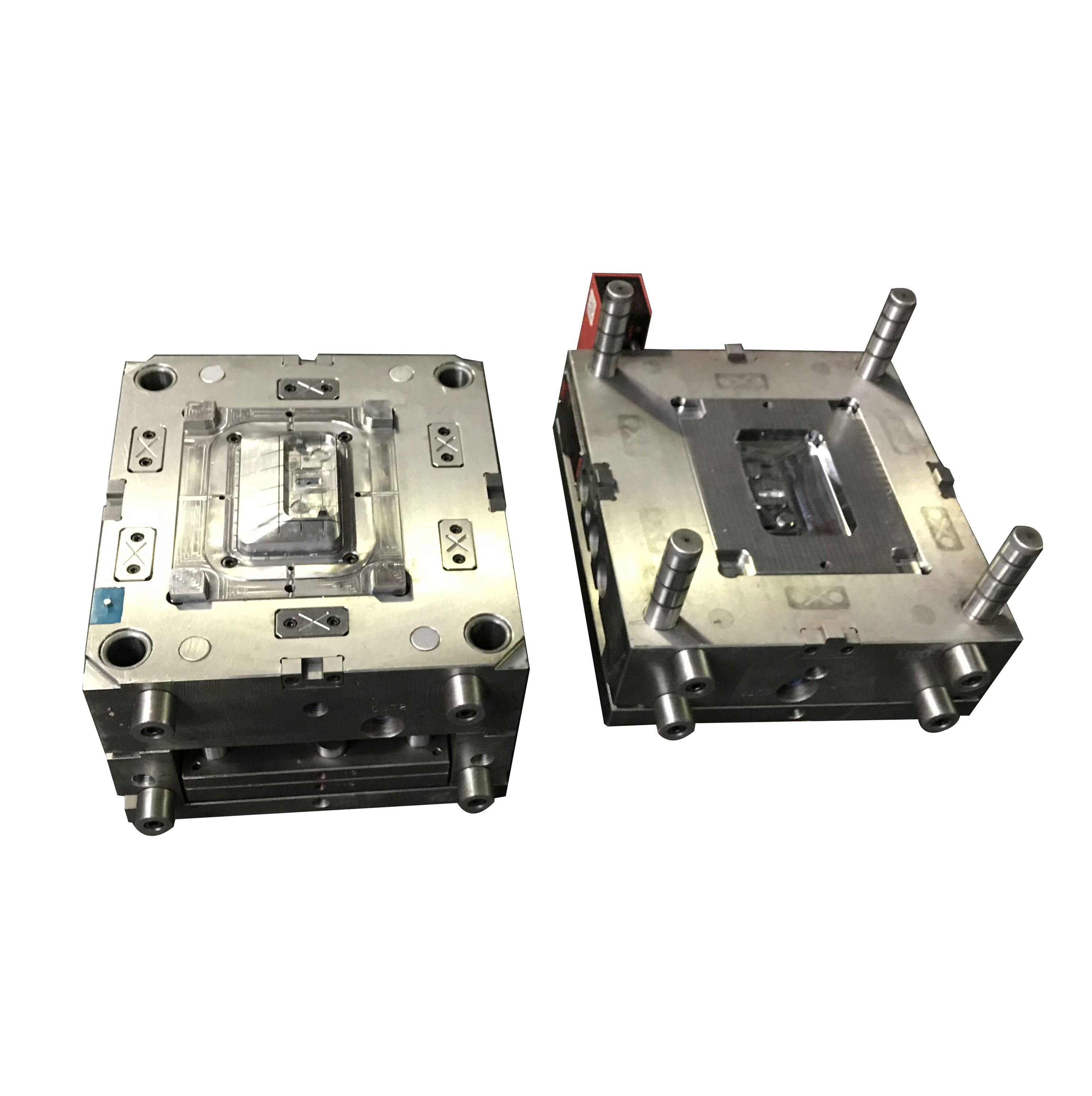

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.