Moldie makes all kinds of stuff out of plastic. You know I do plastic parts for everyday products, from toys to phones to even car parts! Moldie employs a specific manufacturing process known as plastic injection molding. This technique is significant because they can produce a high volume of parts all at once. So, this makes it faster and cheaper for them, which is helps everyone!

They need to come up with a plan before Moldie can manufacture any products. This means determining some key things. You don’t know what the part is for first. For instance, if a thing is for a toy, a phone, or a car? Now, they must figure out how large the part should be. We care which is because the size needs to fit the customers preference. Finally, they consider the part’s appearance. At times, they’ll even make a small model, or a sketch of the part, to assist themselves in the drawing stage. Once they have a good design, they run a program on their computers that helps them create a mold.Additionally, they also use a computer program that helps them create a mold that perfectly fits the part. This mold is so important because it forms the plastic into the appropriate shape. Once that is done, they can finally start making the actual parts!

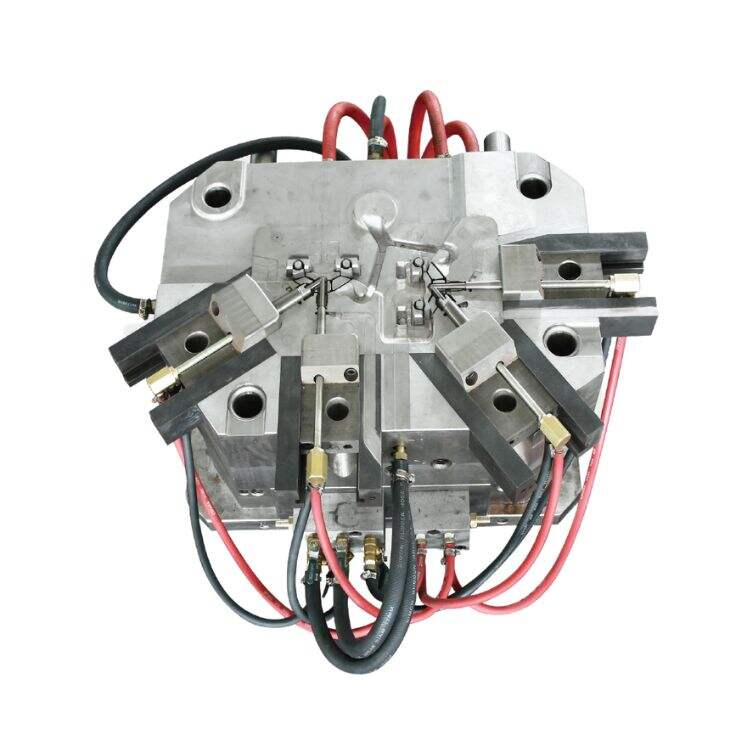

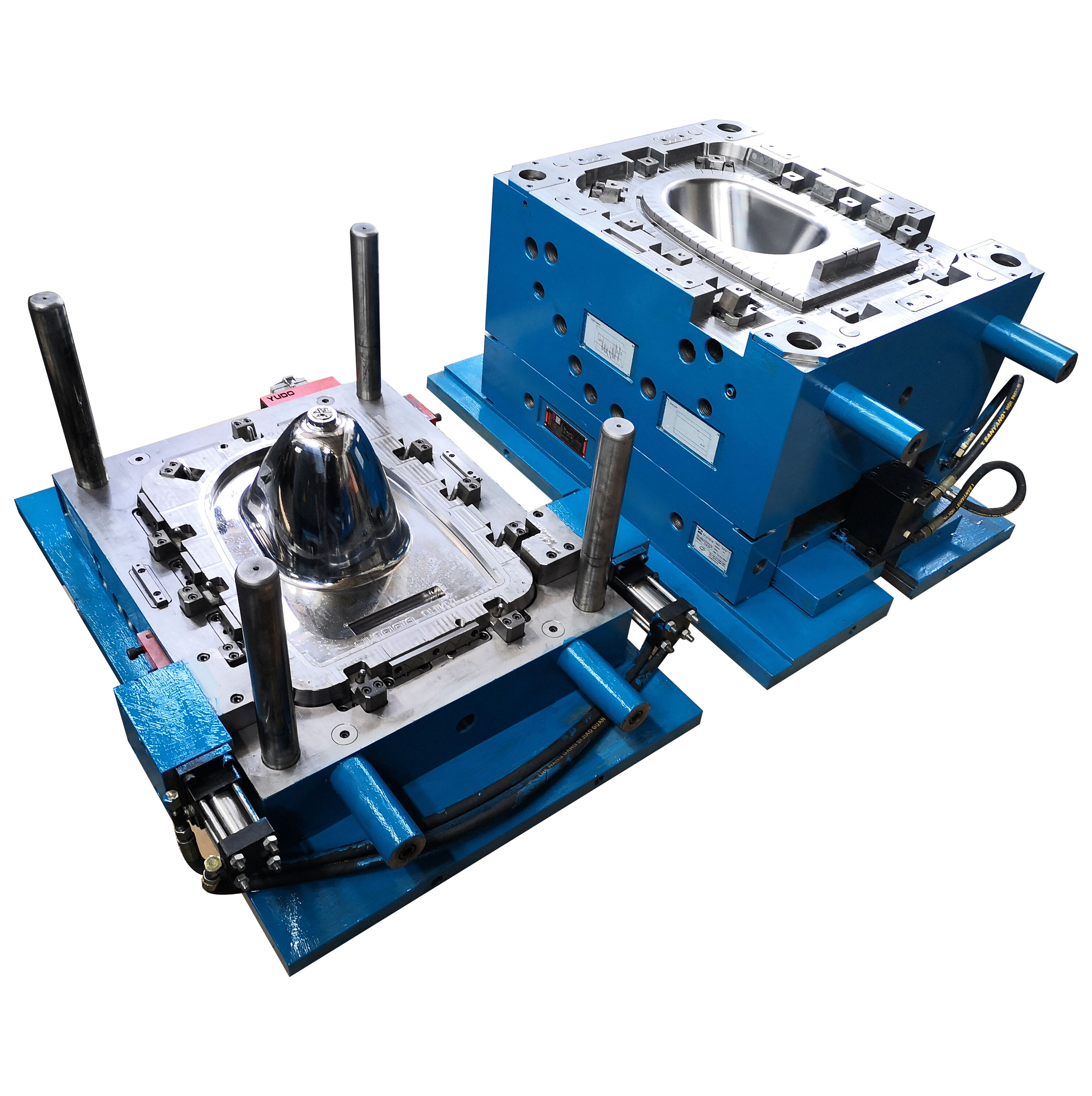

The mold that Moldie creates is industrial-grade and uses metals such as aluminum or steel. Because these metals are hardy, the molds can be used for extended periods. So what the molds are not just blank pieces of metal They have miniature holes and channels in their interiors where the melted plastic will run. This is where Moldie gets special help with technology. The machines that make the molds can create very precise designs that help ensure that the plastic flows just right into every part of the mold.

At the time when parts need to actually be made, Moldie will place the mold inside a specialized machine known as an injection molding machine. This machine melts and goo guys, a plastic pellets until they goo. The machine then injects the melted plastic into the mold through the channels. The plastic cools and hardens to take the form of the mold. And once the mold is opened the new part popps right out! Surmising an inert hunk of plastic will become a finished part is something I find exciting.

What is super exciting about Moldie is they can take an idea from someone and actually turn that into a product that can be used. For example, someone has a cool idea for a new toy, but they don’t know how to create it, and Moldie can help! They’re able to take that idea and create a mold for it. Then there are many copies of the toy and it can be sold in stores all over the world. This allows for much of it to be enjoyed by the kids! This is very useful because when you make things by plastic injection molding, many parts can be made in a single go, and they are all exactly and perfectly replicated. This is particularly important for cars or phones or other things with a lot of parts that need to work well together.

Moldie has already been grinding away to improve his parts-making skills. Injection molding is an intricate process that requires years of practice and mastery. Of course, the process is not perfect, and sometimes things can go wrong. And if any bubbles form in the plastic, or some sections get stuck in the mold, just throw all this in the trash. And this is why Moldie's employees need to be very careful and stay attentive throughout the process.

Incredibly vital stuff at Moldie, as it lays the groundwork for a host of different products. There are countless things we encounter on a day-to-day basis that contain some component made of plastic! Many products wouldn't even be possible without companies like Moldie. They help ensure that toys, phones and cars are assembled properly and outfitted with the right parts.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.