Wanting to make your home looks special and fancy? Molding Over Molding | Moldie If you are looking for a unique touch to add to your rooms, here is a cool idea from Moldie — plastic molding! This playful manner of decorating can truly enliven your environment. It brings layers of beauty and style into any room of your home, adding warmth and inviting approachability.

Molding over molding is an amazing way to help your home look better than ever. This is a great technique for decorating various elements including door frames, windows, arches, and ceilings! Just imagine how much prettier your rooms get with beautiful lines and shapes. Layering pieces of molding, you can achieve a lean and tidy appearance that helps make your home feel unique and modern.

One of the coolest aspects of injection molding, though, is the added layer of styling it adds to your rooms. This is ideal as it makes your home appear different and incredible! Combining different types of molding together can give a design a lot of character and personality. For example, you might do a wide piece of molding at the bottom of a wall and a thinner piece near the top. "This can provide a beautiful contrast that grabs someone and makes them say, "Wow! "

There are multiple molding over molding applications depending on your desired look. If you prefer a traditional style, use a combination of baseboard, chair rail and crown molding. These vintage styles are nice and cozy for your home. However, for a more modern appearance, pick designs with straight lines and fewer details. They can make your house feel fresh and clean. The choice is yours!

There is louder than molding over molding you can do to give your home a nice aesthetic. For vintage enthusiasts, there are also ornate and elaborate molding options that feature tons of intricate detail. That can imbue your rooms with a sweet, period ambiance. A molding that is sleek and simple is perfect for you who has a modern style. The number of options is endless, and molding over molding can fit in with any design style you want.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

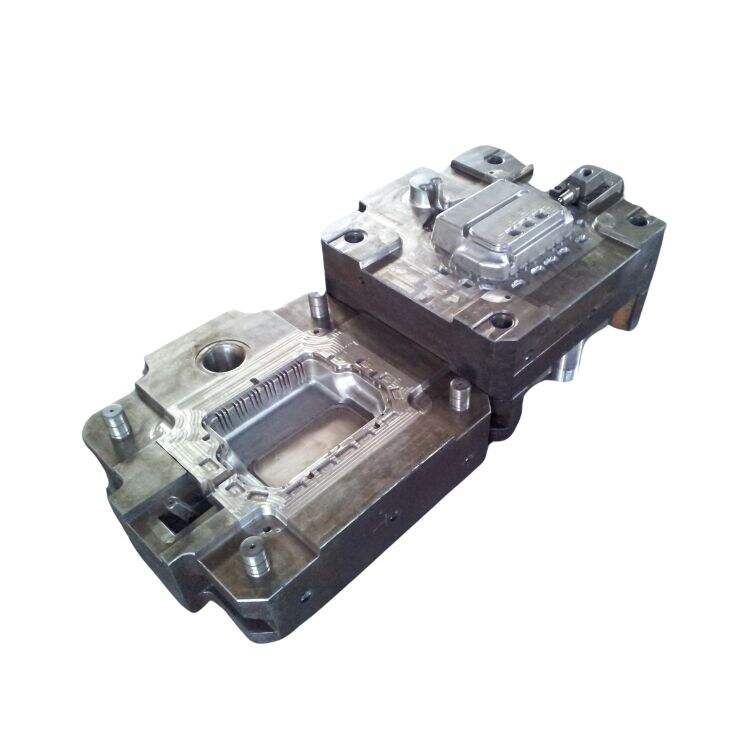

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.