Who we are Moldie is a skilled mold manufacturer applicable to many industries. Moulds are firm shapes that are used to create lots of different items, like toys, tools and parts of machines. Our engineers are very professional and develop efficient and innovative measures to produce molds faster and more accurately. They focus on creating molds that are perfect every time with precision by operating the latest machines and modern technology. All molds will be checked and tested before shipping to our clients to ensure they are perfect.

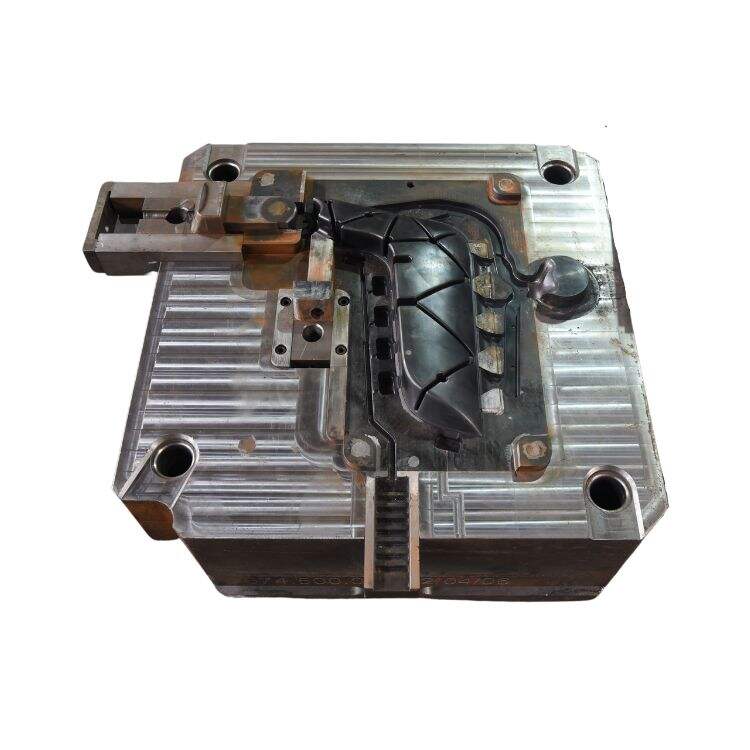

Each customer has different needs and require different services. That is why we are happy to provide them with specialized injection mold solutions that are tailor-made for their needs. We are strong believers about working especially closely with our customers. We listen to exactly what they want so we can get the mold designed to suit their needs right away. Our in-house team of designers and engineers ensure that the moulds are formed to specifications as per client requirements. The molds we produce are constructed of solid and quality materials.

At Moldie, we care very much for the environment, and we want to do our part to help save it. We know plastic waste is a major global problem, but that’s why we make an effort to lessen our impact on the planet. Our molding processes utilize recycled materials whenever possible, which can help reduce waste. We have also installed energy-efficient systems in our buildings to reduce pollution and contribute to a smaller carbon footprint. Our molding processes in our factories are as efficient as they can be to help us create less waste and be more gentle on our planet.

Please have no doubt, however, that we pride ourselves on our mold quality. We put a lot into designing and making sure that our molds will hold up after a lot of use and will meet high standards. Even with frequent use, young kids will not hurt it — only safe and sturdy materials were used to construct the tool. One of our goals is continually finding ways to improve the mold-making process. And whilst we want to be making as many molds as possible, we also want to ensure our customers get the best quality molds, and therefore, products.

We at Moldie, believe in relationships that last a life time. They rely on us to deliver quality molds with long life span. That’s why we partner with our customers to deeply understand their needs and provide them with the best possible solutions. Our staff is available to answer any questions you may have and provide excellent customer service. We strive to be a trustworthy partner for all molding design and building requirements.

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.