Using die casting, Moldie's smart technology creates high-quality plastic injection products quickly and accurately. Die casting is a unique process in which metal is molded into intricate shapes using a mold. This is accomplished by forcing the metal into the mold under extreme pressure. When the molten metal cools and solidifies, it assumes the form of the mold. The products are given a smooth finish with this method in addition to ensuring they are manufactured in an appropriate manner

Die Casting Die casting technology is extremely essential in the manufacturing world. It enables manufacturers to produce intricate shapes and patterns with ease and precision. Die casting technique is one of the best things which is making many products in a very short span of time. This speed is a massive boon for companies that need to churn out a lot of items, and quickly. Using the die casting process allows businesses to create what their customers want without wasting time or material.

So let us take an opportunity to see the benefits of using die casting technology in manufacturing parts here: Its most significant benefit is that it is capable of creating top-notch injection part products extremely quickly. This allows businesses to meet customer demand and remain competitive in the industry. In addition to speed and accuracy, die casting ensures quality and a uniform finish on the products. This is crucial since consumers anticipate that the products they purchase will always be both presentable and functional.

Die Casting technology is also extremely versatile. It is capable of producing dissimilar sized and weighted injection parts products which is important to produce different type of items. This versatility enables manufacturers to create and manufacture various products without having to significantly modify their machinery or processing methods.

Die casting technology is evolving too, as with technology keeps changing and improving. We have new tools like the robots and automation to make even more advancement in the die casting process. At Moldie we take advantage of the best die casting technology can offer so our customers can achieve their goals. We want to ensure that we are using the right tools and materials available so that we can deliver the best value product.

To create products that exemplify high quality without much effort, Die Cast technology is one of the most effective tools. Leveraging die casting, manufacturers are able to quickly create complex shapes that meet customer requirements. WE are committing to maximize the use of die casting technology at Moldie. We aim to produce the best production for our customers. We hope with this technology, we can ensure our products are not only well made but also on time.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

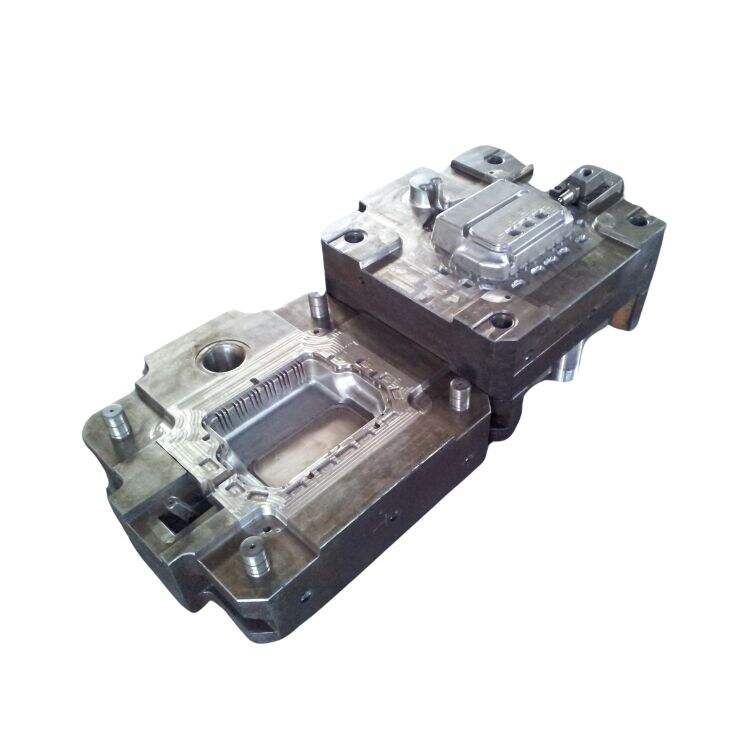

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.