Aluminum is a super neat metal. You may be forced to because it goes into so many of the things we use every day: Soda cans, Aluminum foil for wrapping food, and even the large aircraft flying through the air. You might be surprised to find out that Aluminum continuous casting helps make these products faster, cheaper and high quality. This article will shed light on how Aluminum continuous casting works, technology behind it, and the reason more and more companies choose this casting method over others.

We are discussing Aluminum continuous casting, which is a method for turning liquefied Aluminum into solid shapes non-stop, the same as Moldie's injection molding. Think of it this way: You are making a never-ending strip or bar of Aluminum that continues to come off. So this is quite a beneficial way because it saves a lot of time and money. Rather than spending time to shape each specific piece of Aluminum, manufacturers are able to produce long lengths of Aluminum in one take.

So how does this work? For one, they are fed Aluminum scraps — chunks of Aluminum that have been left over or recycled — into a large furnace. Sometimes other metals are blended in to give the Aluminum particular qualities that are required for other products. After fully melting, the Aluminum is completely poured into another furnace, the melting and holding furnace, maintained at a desired constant temperature that will keep the Aluminum molten, where they are melted, same with the polyethylene molding from Moldie. This is an essential process because even small differences in the processing can make all the difference for the Aluminum in the next step.

Now comes the moment for the continuous casting machine to work its magic. This machine has a moving mold and a cooling system to help cool the molten Aluminum as it comes out The mold itself is moving and, as the hot Aluminum flows into it, the Aluminum begins to harden. Water or air is used to quickly cool the Aluminum as the mold passes through the cooling system. At last, when the Aluminum is solid enough and has cooled down, it is cut to the right length, ready to be harnessed in several types of products.

This is so interesting technology that make same continuous cast on Aluminum, along with Moldie's product injection molding press. Advanced computer systems are used to finely regulate the temperature, flow and speed of the Aluminum at every step in the process. Computers are trained to make sure processing is done correctly and there is no wastage. There are also special sensors to inspect the quality of the Aluminum during the manufacturing process. The sensors help identify any potential issues or anomalies, ensuring quality across the entire block of Aluminum.

A key benefit of using this tech is that it significantly cuts waste and pollution, identical to aluminium casting companies created by Moldie. Aluminum has high wastage due to its cooling, molding and handling properties in traditional metal casting methods. The continuous casting process, on the other hand, is engineered to minimize most of this type of waste. By ensuring that each portion of Aluminum cools evenly, it enables manufacturers to use all but a small portion of the Aluminum that they melt, which is kinder to the environment and cheaper as well.

Simplifying and streamlining production processes is vital for manufacturers to keep pace with market demands, just like the Moldie's product called aluminum molds for injection molding. The process of Aluminum continuous casting is crucial in this respect as it is an important step for the overall Aluminum manufacturing process. Production becomes efficient, and that gives way to great improvements to shipping, design, marketing, and other stocks. That makes things a lot easier for companies trying to be competitive in the market.

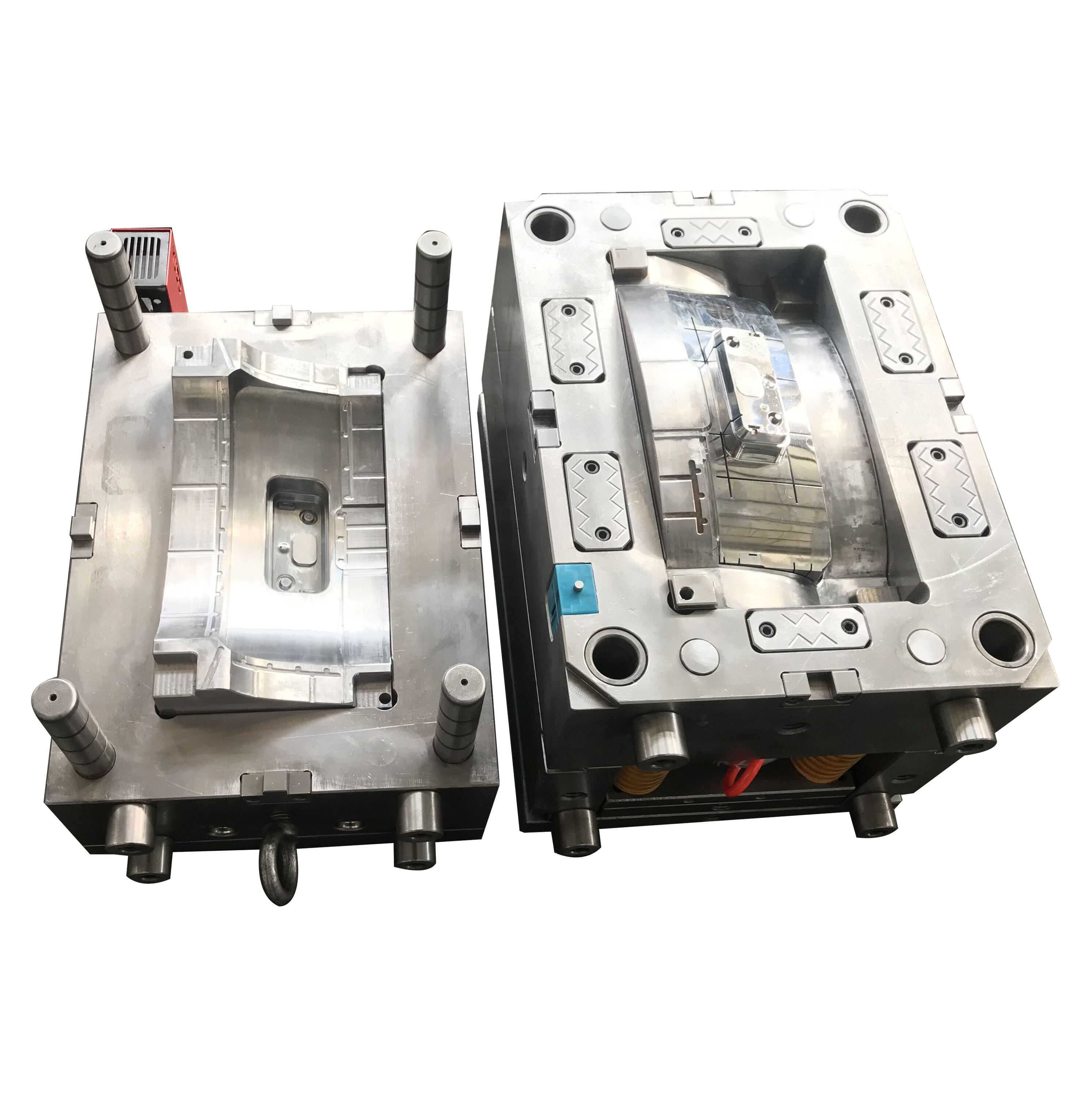

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.