Aluminium die casting is economical as well since it involves less material than other metalworking techniques. In moldie aluminium casting, liquid metal is poured into a mold, or hollow shape. After making the metal cool, it solidifies to assume the shape of the form. Aluminium is much lighter, which means it is easier to work with, and thus allows you to produce more parts without breaking the bank. You win when you can make more parts for less money!

Sand casting: This is the simplest technique and are usually employed to create bigger parts. Sand casting: sand is packed around a shape called a pattern. When sand is prepared molten aluminum is filled in sand. Once the metal cools and solidifies, the sand is taken away revealing the finished piece. It is relatively cheap, easy to perform, but perhaps less accurate than other methods.

Investment casting: This process is slightly more complex. It begins with a wax form called a pattern. The wax pattern is covered with a ceramic material to form a mold. The wax is then melted out, leaving a hollow cast behind when the ceramic is ready. The space is then filled with molten aluminium. Investment casting best quality but also the high cost.

Aluminium casting cost usually varies depending on a few considerations. The major factor is the size and complexity of the part you want to make. Bigger, more complex parts take more time and material to produce, so they have a higher casting cost. The other concern is the kind of tools and machines required for the moldie aluminum metal casting. Use: Certain techniques need special devices and tools like the investment cast, and they increase the total price.

For those seeking a way to save some cash on aluminium casting, there are many different routes they can take. For example, try more straightforward forms of casting, such as sand casting. This may not be as precise as die casting or even investment casting, but it can provide a cheaper solution for larger or simpler parts. If you don’t require parts that are super high-resolution or highly accurate, this method is a viable option.

Work with a casting company, such as Moldie, is another method of saving money. While they can also help you in designing your parts which can be cast well. Optimizing your designs means using less material in production and less time in production. This ultimately results in lower costs and can save you some money while still obtaining quality parts.

There are many reasons that make aluminium casting a wise option for manufacturing. First, moldie aluminium metal casting creates heavy-duty and reliable parts resistant to heat and stress. This suggests that the component areas which happen to be produced from aluminium can be used so many of each of these specific specialists and also they are going to last somewhat longer. This is due to the fact that aluminium is a very versatile material, and that it can be used for a large variety of applications, including automotive parts, consumer products, and even electronics.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

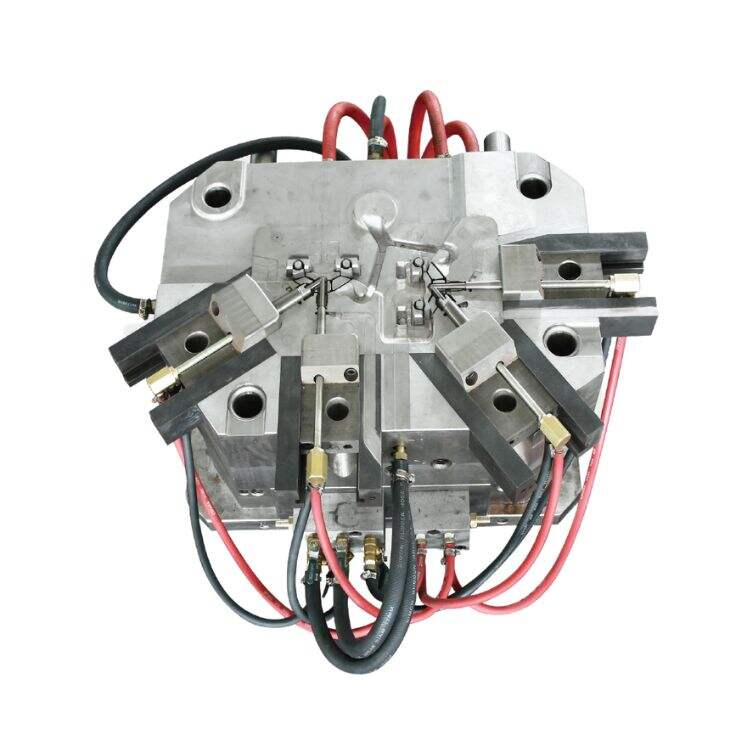

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.